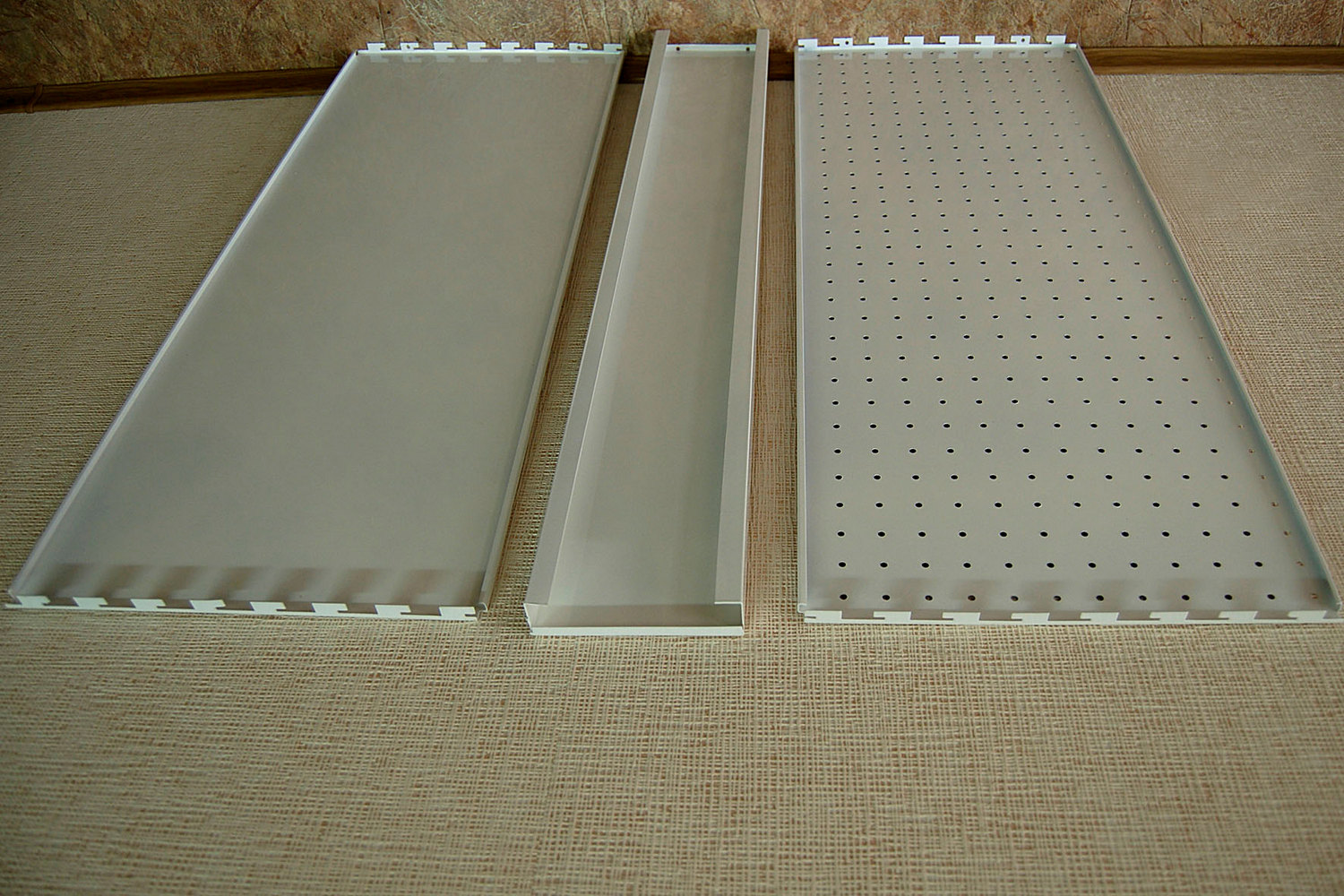

Shelving systems

Solutions inspired by your ideas and our experience

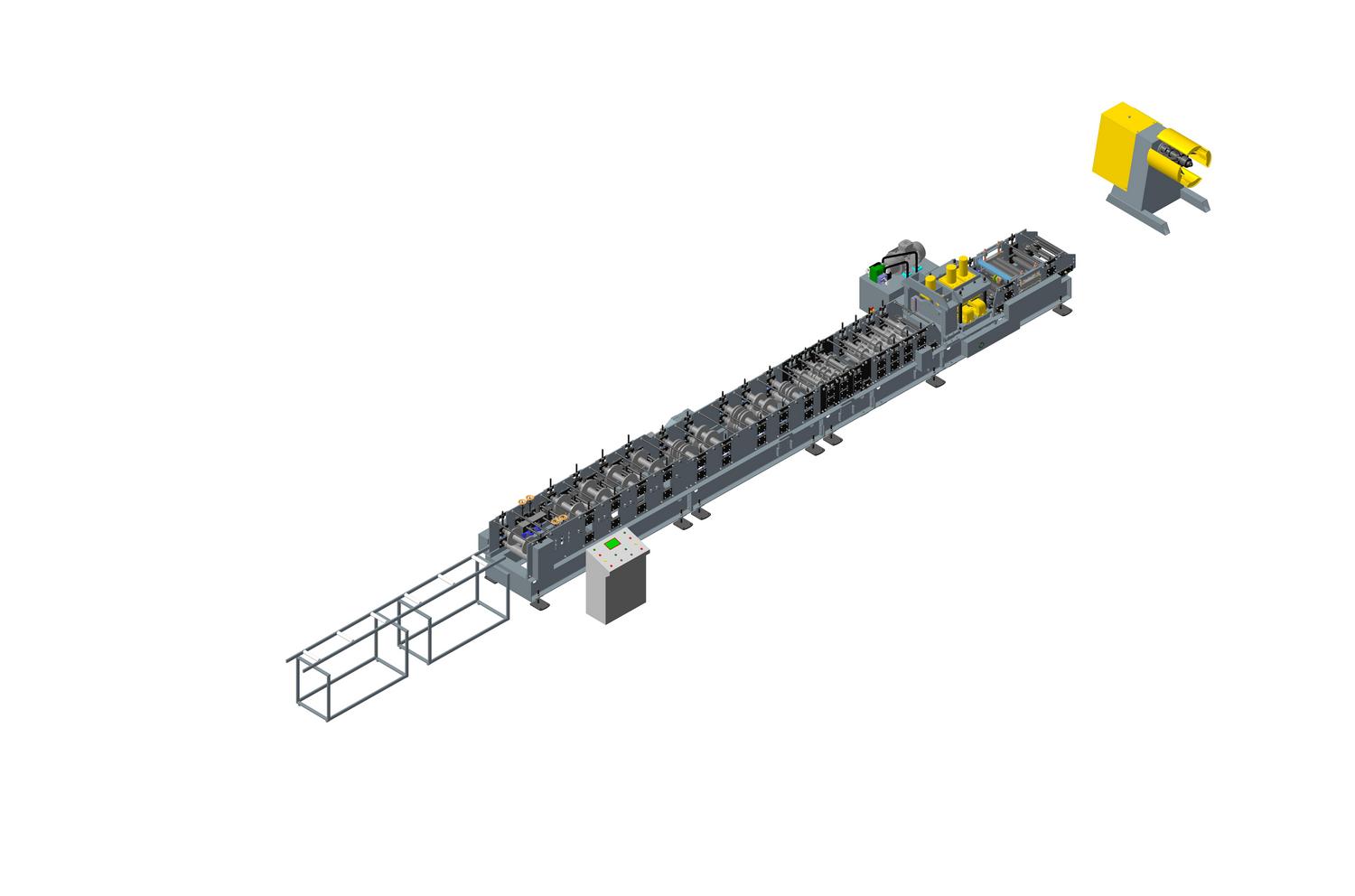

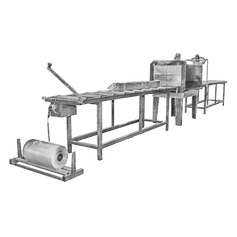

Equipment

Decoiler

1 pc;

Straightening device

1 pc;

Automatic punching device

Roll forming mill

Roll forming mill

1 pc;

Cutting device

1 pc;

Receiving table

2 pcs;

Control cabinet

1 pc;

Options

- Replaceable blocks of profile perforation;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking of the line by the manager);

- Logistics and packaging

Description of the line

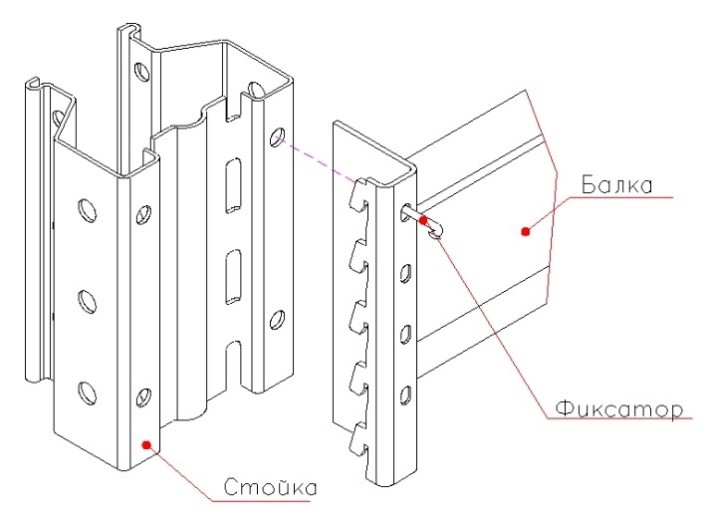

The lines are designed for the production of profiles of rack systems (rack, diagonal, cross-beam, connector) from thin sheet steel 1.5 mm thick.

Specifications

Processed material

Thin-sheet galvanized steel with polymer coating

Thickness of the processed material, max

1,5 mm.

Productivity, not less

6 run. m. / min

Type of straightening device

Electromechanical, five-roll

Punching device type

Electromechanical, servo drive

Punch Controller Function

Programming a variable feed pitch of the workpiece

Number of double strokes of the press stamp

80 pcs/min

Type of roll forming mill

Rack-mountable

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming mill, equipped with a frequency converter

Operation personnel

1-2 persons