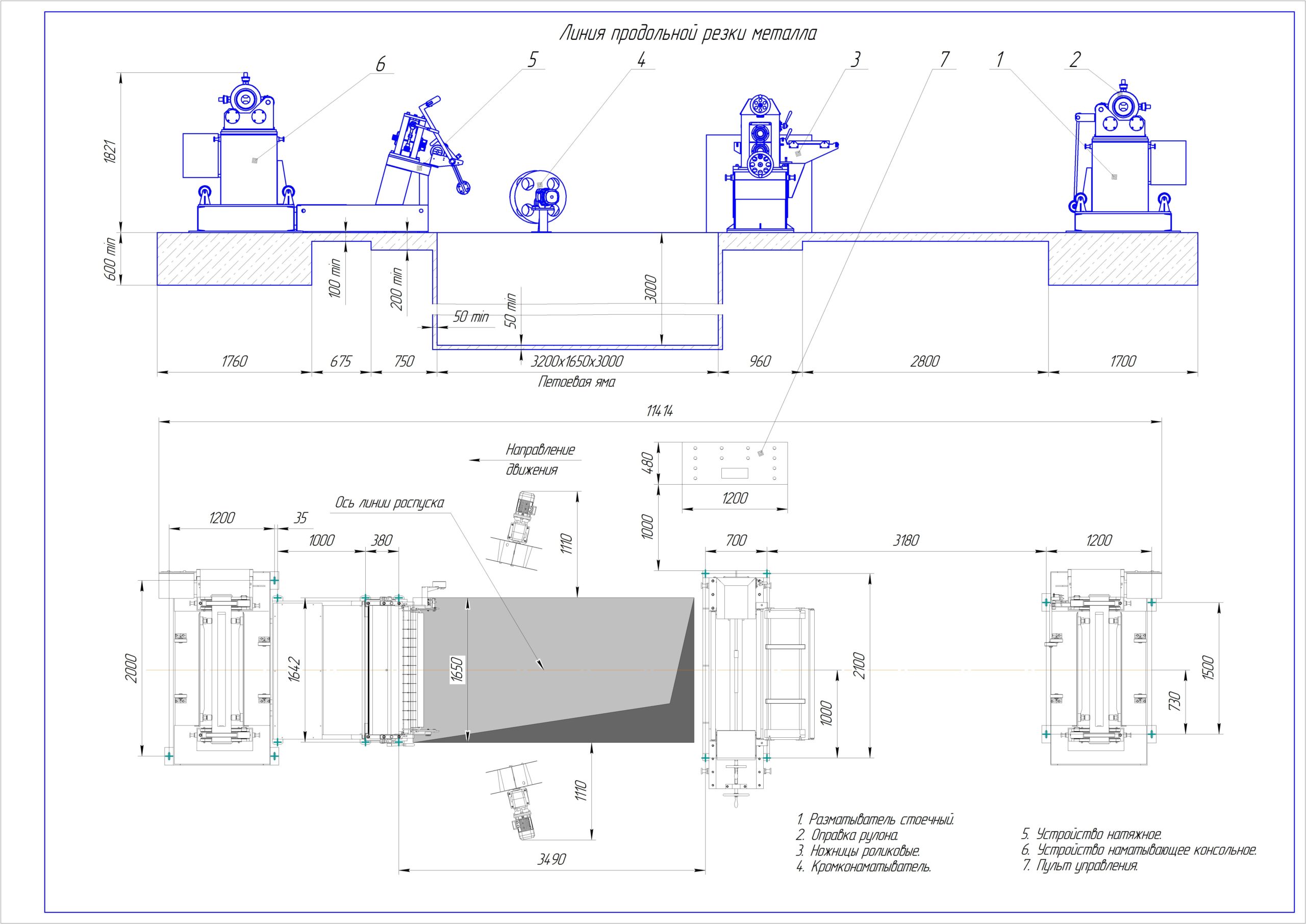

Slitting lines for steel

Solutions inspired by your ideas and our experience

Equipment

Decoiler

1 pc;

Metal filling device

1 pc;

Straightening unit

1 pc;

Roller scissors

1 pc;

Edge winders

2 pcs;

Winder with tensioner

1 pc;

Control cabinet

1 pc;

Loading / unloading carts

2 pcs;

Options

- Replaceable blocks of the correct device;

- Paper application/reminder

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking of the line by the management.);

- Logistics and packaging

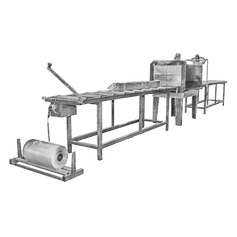

Description

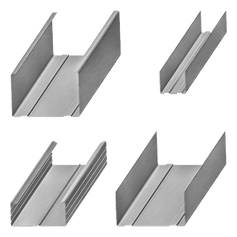

The line is designed for straightening and cutting and winding coiled steel with a thickness of 0.3-6.0 mm. into strips of a given width (strips). Strip – is an integral part of the roll forming system, each roll forming line requires a piece of a certain width.

Specifications

Processed maerial

Galvanized sheet steel from continuous lines with protective and decorative paint and varnish coating, aluminum, stainless steel

Thickness of the processed material

0,3-6,0 mm.

Performance

100 run. meters/ min

Accuracy of cutting into strips

± 0,2 mm.

Straighetening device

Serves for straightening metal before cutting, relieves residual stress in the metal.

Type of straighetening device

Electromechanical

Number of straightening shafts of the straightening unit

According to the technical specifications

Feed rollers

Installed on the straightening mill

Type of roller scissors

Electromechanical

Knife material

Alloy steel, hardness 55 ... 62 HRC

Work mode

Semi-automatic

Control cabinet

Provides automatic line operation after loading the material into the line

Operating prsonnel

2 persons