Knauf profiles

Solutions inspired by your ideas and our experience

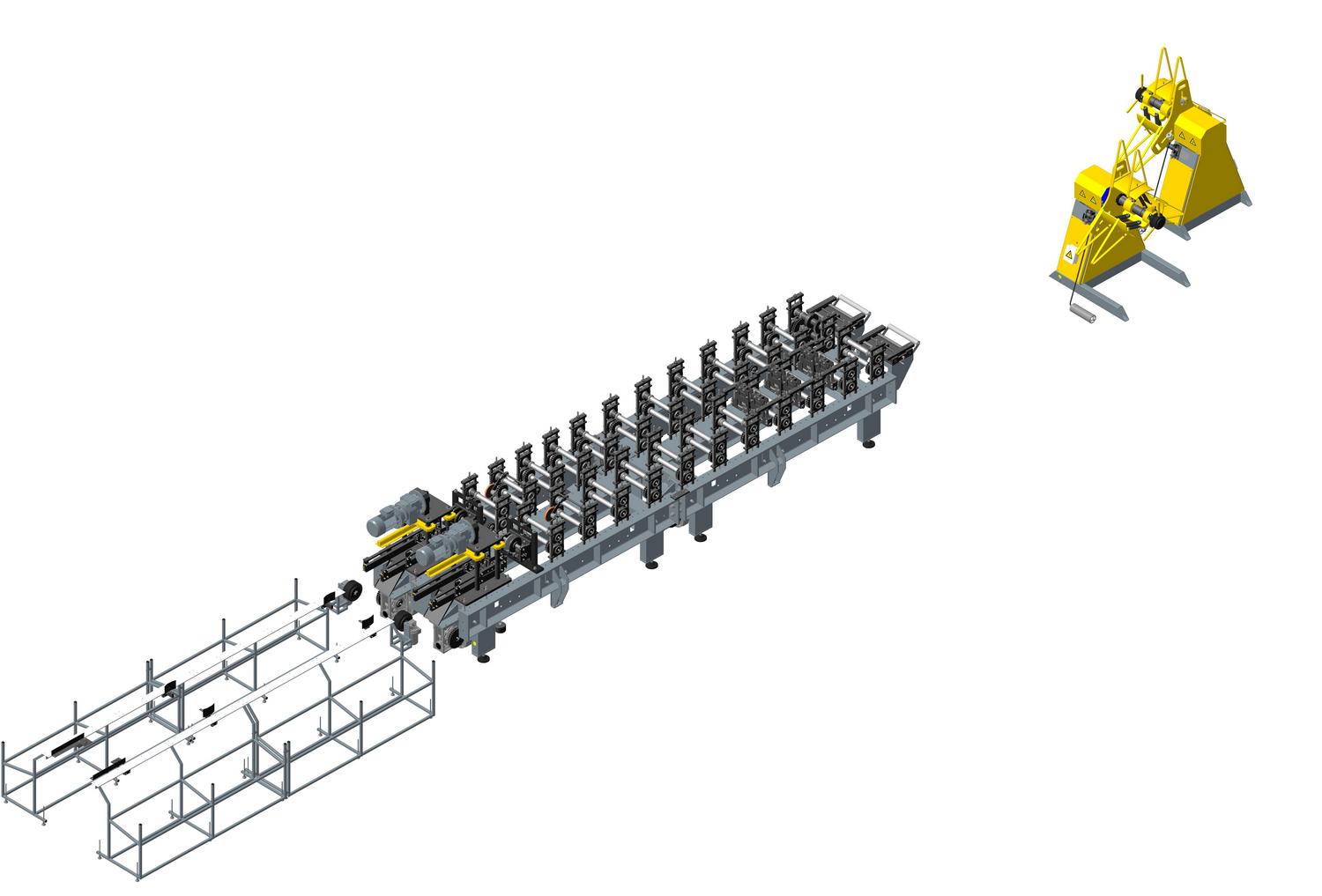

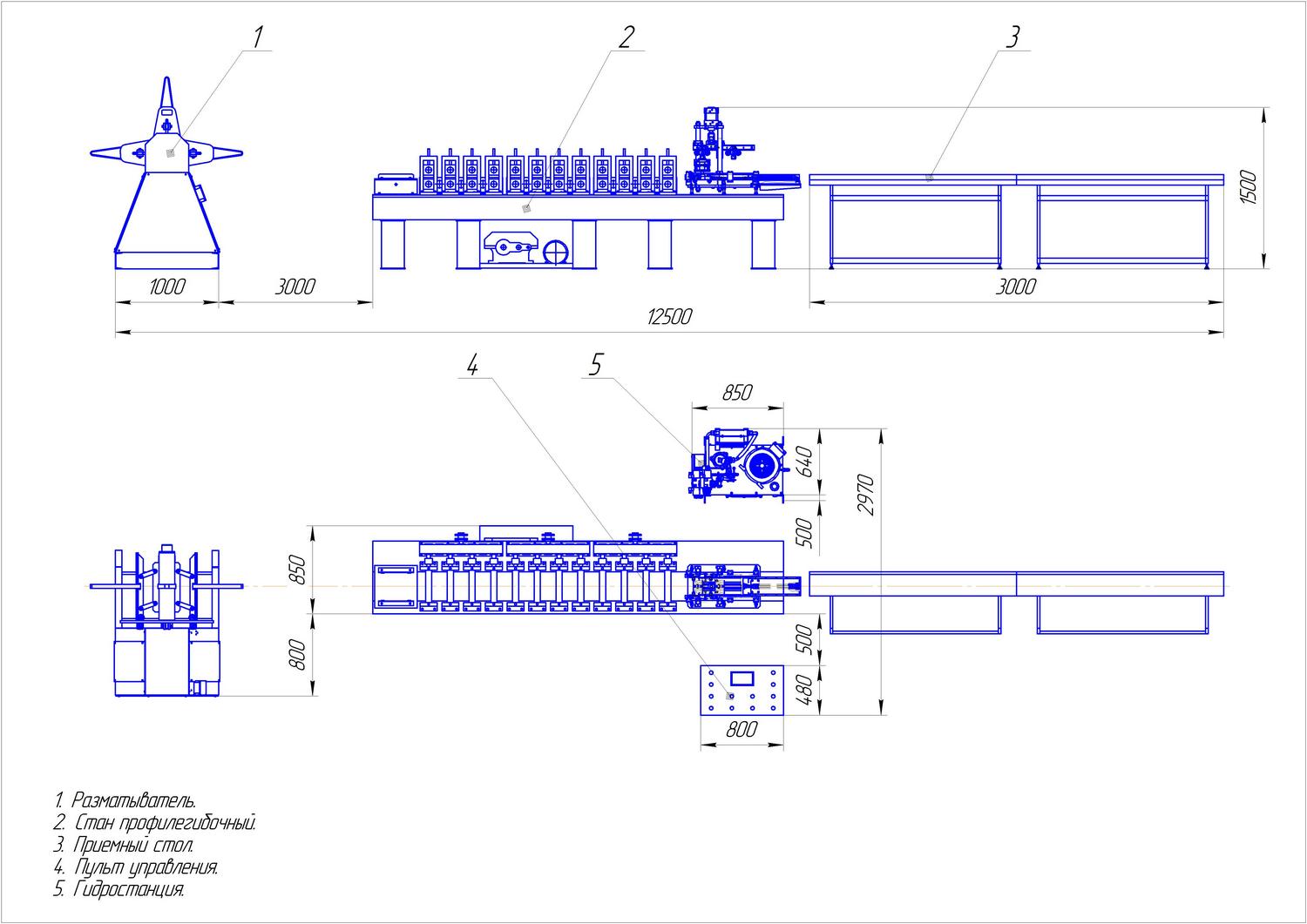

Equipment

Decoiler

2 pcs.

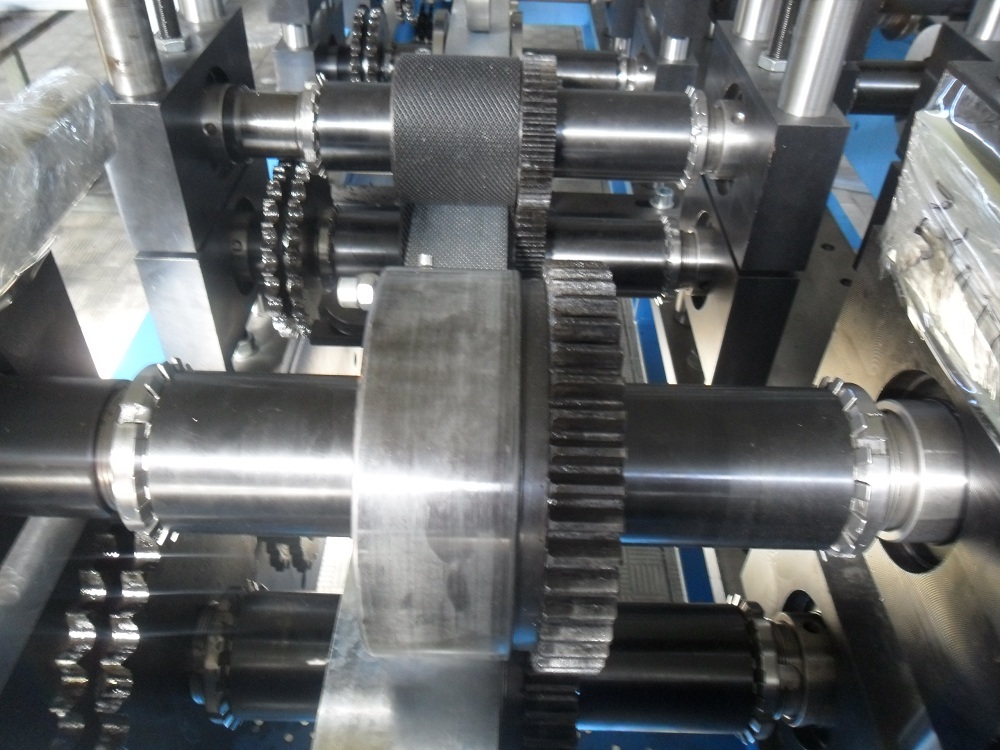

Roll forming mill

1 pc.

Cutting device

1 pc.

Receiving table

4 pcs.

Control cabinet

2 pcs;

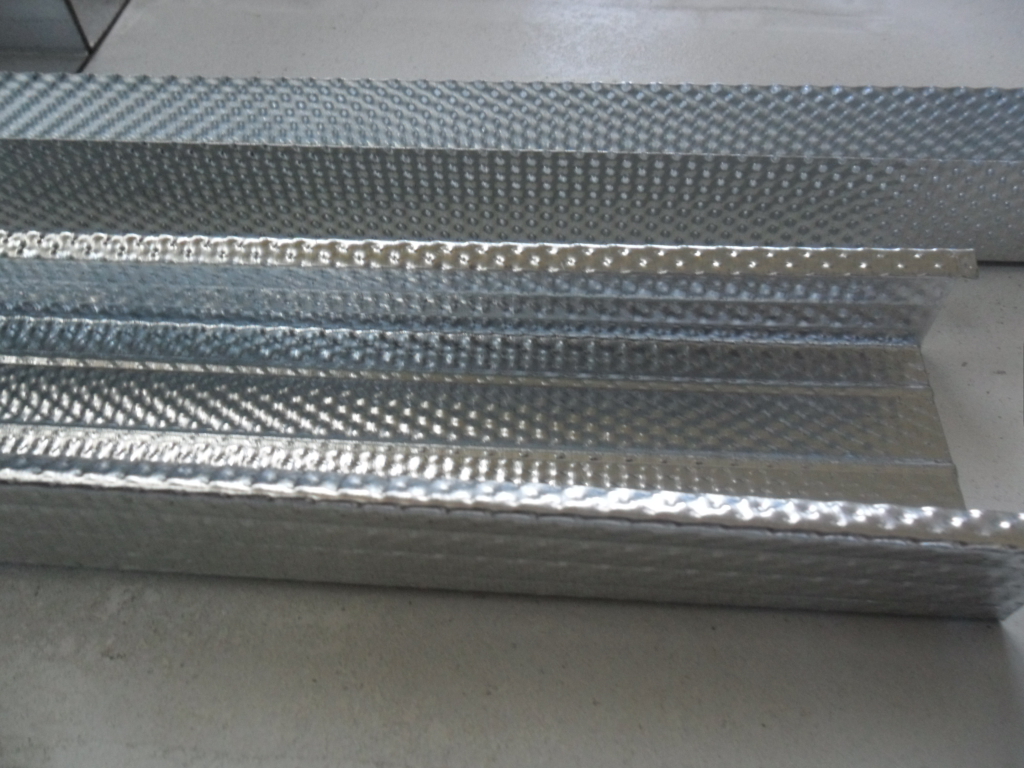

Options

- Knurling rollers;

- Rollers for punching technological holes in profiles;

- Fences, sensors, cameras in critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking by the management of the line.);

- Logistics and packaging.

Description of the line

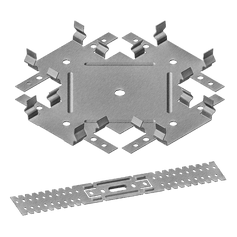

Lines for the production of profiles for the installation of gypsum plasterboards (KNAUF system) – CD, UD, CW, UW from thin-sheet galvanized steel with a thickness of 0.3 – 0.6 mm.

Specifications

Processed material

Thin-sheet galvanized steel n (steel grade DC01, DC04, application: cold rolling)

Thickness of the processed material

0,3-0,6 mm

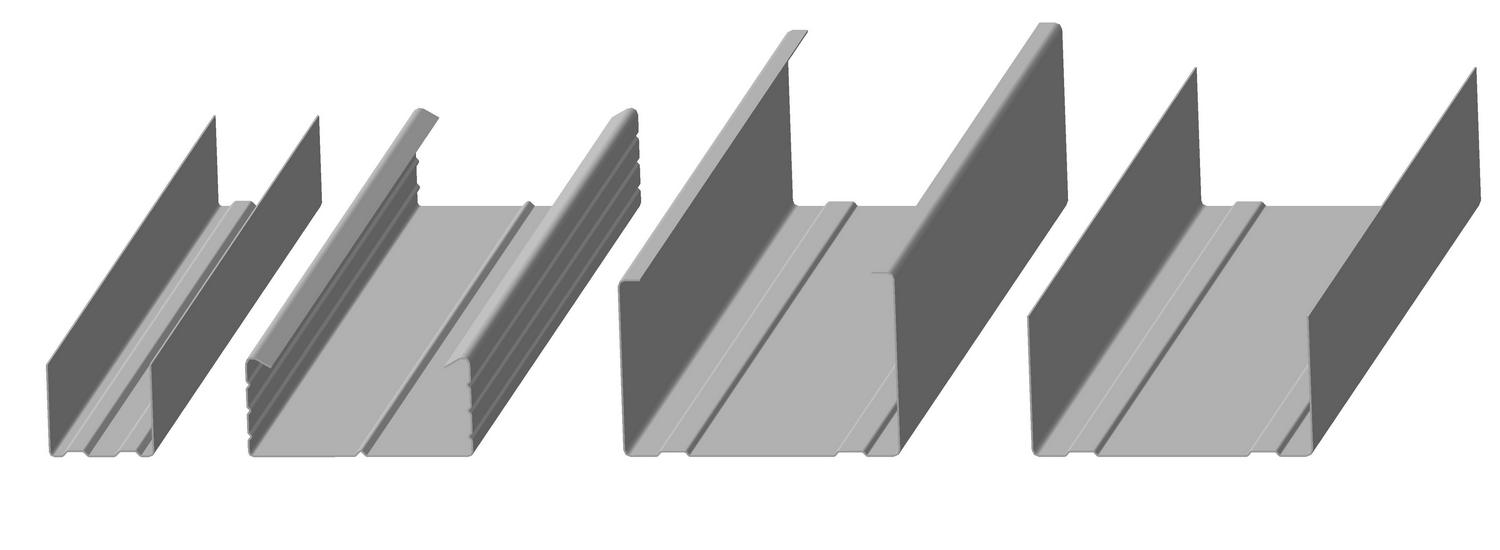

Type of produced profile

CD, UD, С – 50, 75, 100 ; U – 50, 75, 100

Workpiece width

123; 80; 157; 182; 207; 129; 154; 179; mm.

Profiling speed

100 run. m. / min.

The maximum length of the profile accepted by the pickup table

4000 mm.

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming machine, equipped with a frequency converter

Operating personnel

2 personss