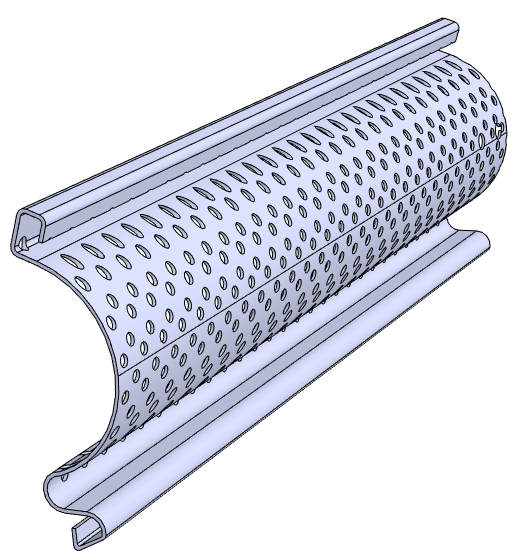

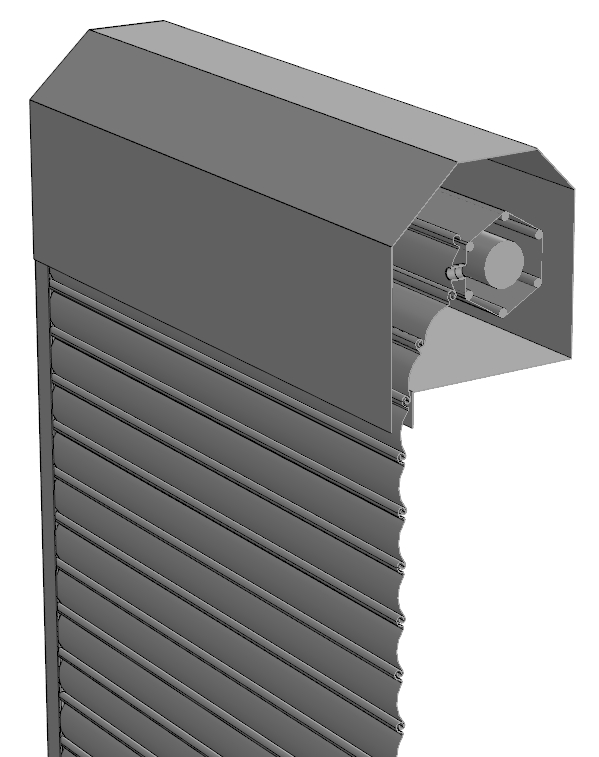

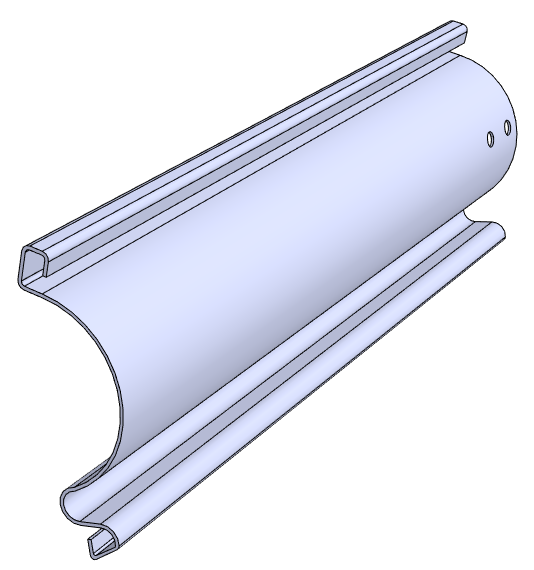

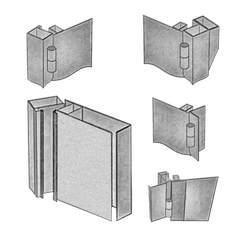

Roller shutter profile

Solutions inspired by your ideas and our experience

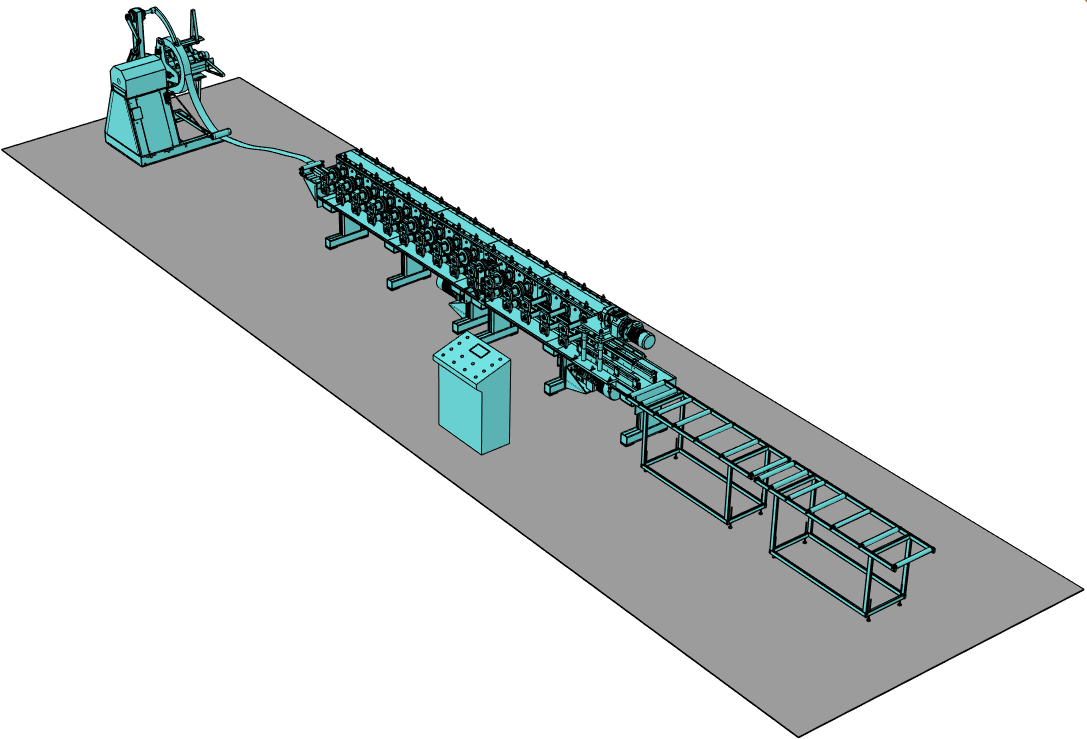

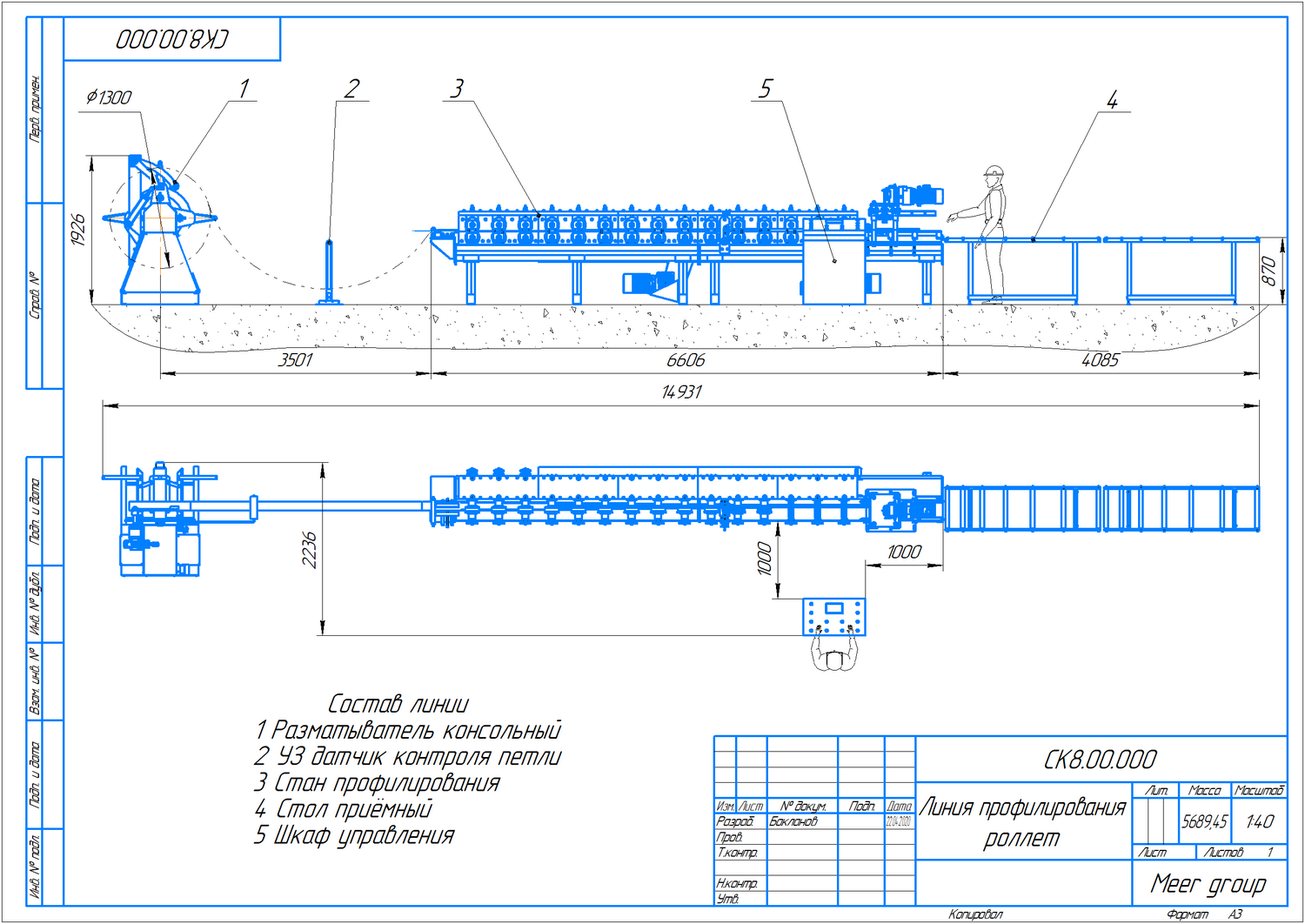

Equipment

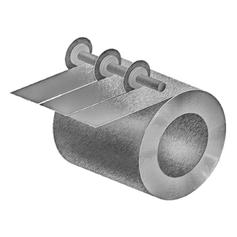

Decoiler

1 pc;

Roll forming mill

1 pc;

Press-stamp

1 pc;

Cutting device

1 pc;

Hydraulic station

1 pc;

Receiving table

1 pc;

Control cabinet

1 pc;

Options

- Film application device;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking of the line by the management.);

- Logistics and packaging

Description

Meer Group manufactures universal equipment for rolling roller shutter profiles.

The main task of roller shutters made of anti-burglary steel profile is reliable protection of the object, whether it is anti-vandal protection or protection from burglars.

Steel roller shutters are not a consumable, but an investment in safety for many years.

All main elements of burglar-proof roller shutters are made of high quality galvanized steel. The roller shutter design is designed with a large margin of safety for long and trouble-free operation, providing high vandal resistance. Galvanized steel with an additional polymer coating provides reliable anti-corrosion protection throughout the entire service life.

Specifications

Processed material

Galvanized sheet steel from continuous lines with protective and decorative paint-and-lacquer coating

Drawings of profiles

According to drawings

Thickness of the processed material, mm

0,3…0,5

Bar width, mm.

According to drawing

Number of streams, pcs.

1-2

Length of bar, mm

From a roll

Productivity run. m./min

20

Number of shaping drive stands, pcs. not less

10

Straightening stands, pcs.

1

Mill drive

Chain transmission from a Varvel worm gear motor (Italy) or an analogue of European production

Installed power of the mill drive, kW *

6 кWt

Filling device

With the possibility of independent cheek adjustment

Method of installing profiling rolls on shafts

Installed on dowels through spacer sleeves. The entire set is secured on both sides with slotted nuts and multi-blade washers.

Changeover from profile to profile on a universal strand

Produced

Requirements for geometric accuracy and quality of the profile.

According to drawing

Forming roll material

Alloy steel, hardness 45…60 HRC to a depth of 0,4…0,6 mm

Place of installation of cutting and punching devices

On the frame of the roll forming mill, at the end of the mill. Punching and cutting is done after profiling.

Number of guide columns ball screw feed, pcs

2

Drive of the cutting device

Electromechanical

Cutting device drive power

2,2

Waste in the cutting device, mm

8

Cutting device dies material

Alloy steel, hardness 55…62 HRC

Overall dimensions (length x width x height), mm *

7850 х 2596 х 1857

Weight, kg *

3480