Metal tile

Solutions inspired by your ideas and our experience

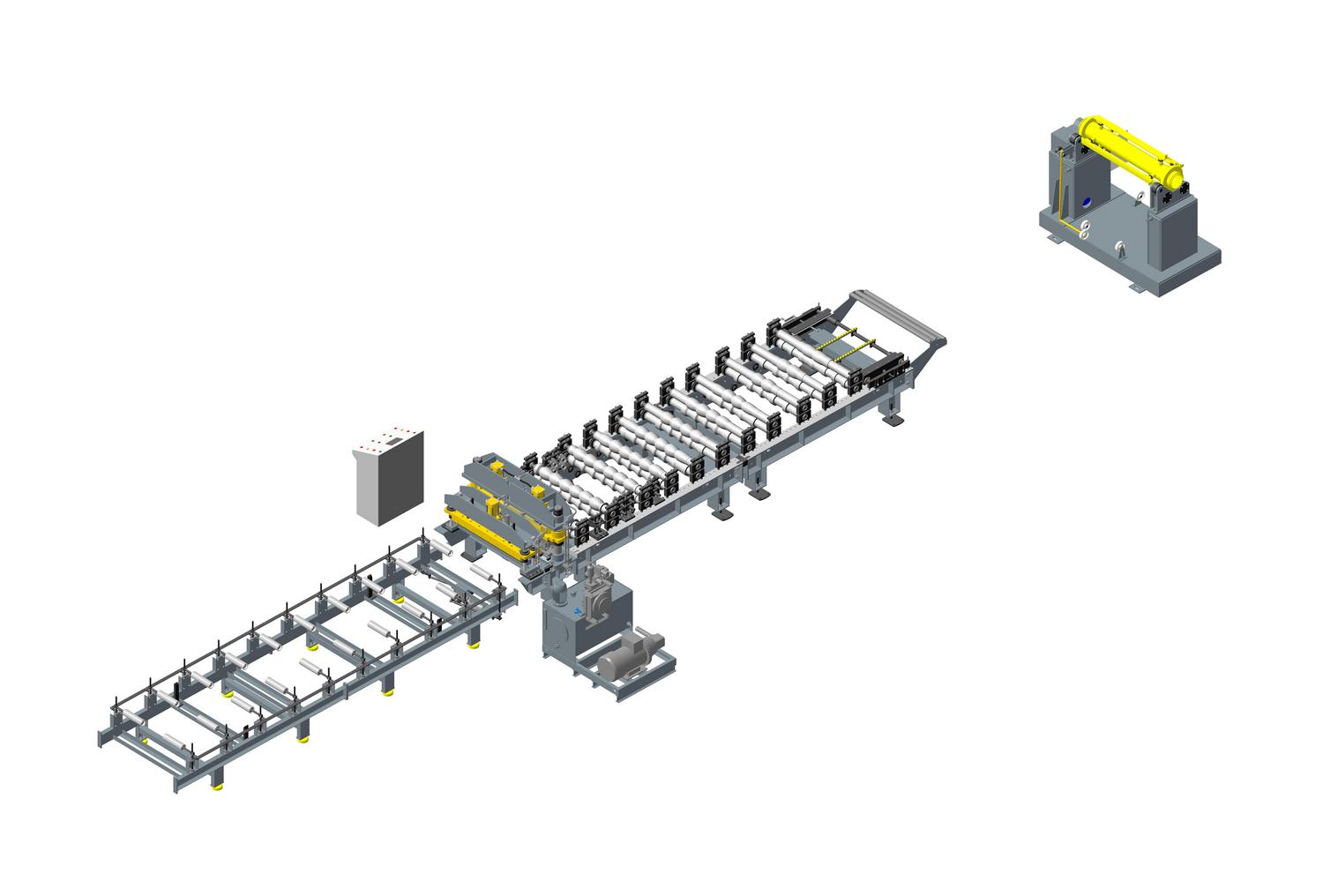

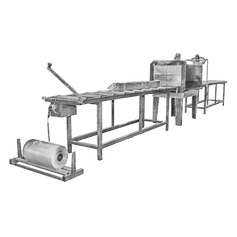

Equipment

Decoiler

1 pc;

Film applicator

1 pc;

Profile Roll Forming Machine

1 pc;

Press-stamp

1 pc;

Guillotine scissors

1 pc;

Hydraulic station

1 pc;

Pick-up stacker table

1 pc;

Control cabinet

1 pc;

Options

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking of the line by the management.);

- Logistics and packaging

Description

This type of equipment is designed for the production of metal tiles of the following types “Monterrey”, “Cascade”, “Dune”, “Adamante”, etc. from galvanized steel sheets with a thickness of 0.4 – 0.6 mm, as well as from metal with paint and varnish and decorative -protective coating.

Specifications

Processed material

Galvanized sheet steel with protective and decorative paint-and-lacquer coating

Thickness of the processed material

0,4-0,6 mm

Workpiece width

1250 mm

Capacity

4-12 run. m. /min

Accuracy of cutting

± 5 mm

Work mode

Semi-automatic

Length of sheets taken by the table with a stacker

2000-6000 mm

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming mill, equipped with a frequency converter

Operating personnel

1-2 persons