Greenhouses

Solutions inspired by your ideas and our experience

Equipment

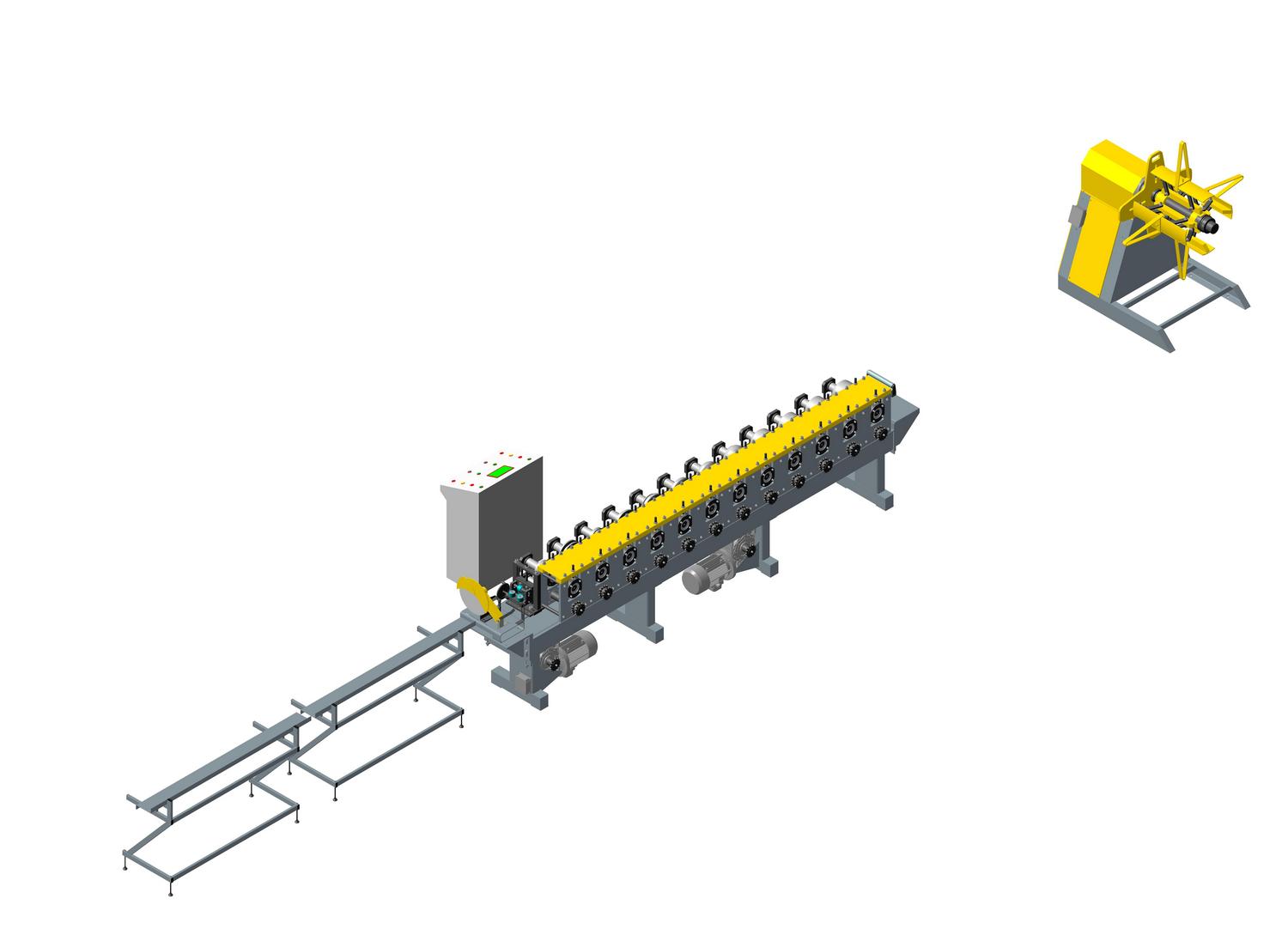

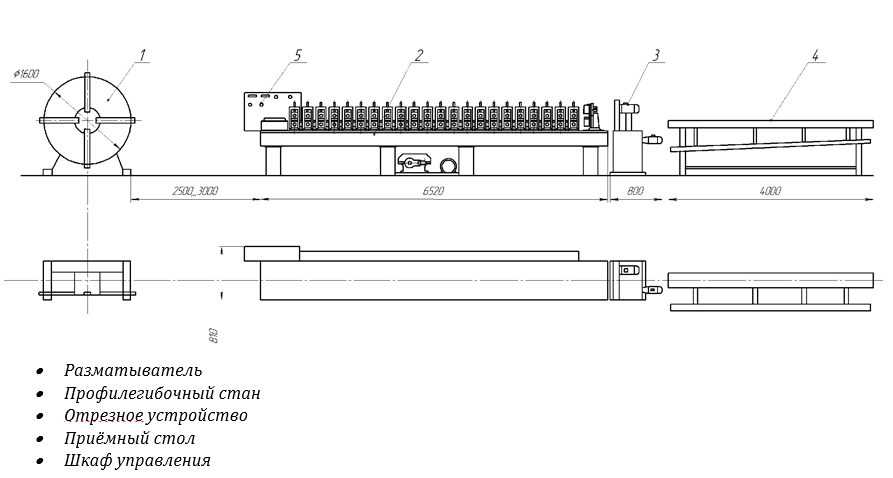

Decoiler

1 pc.

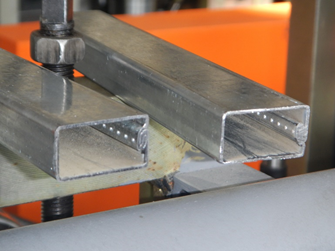

Roll forming mill

1 pc.

Cutting device

1 pc.

Control cabinet

1 pc.

Receiving table

1 pc.

Options

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking the work of the line by management.);

- Logistics and packaging.

Description of the line

Meer Group offers its Buyer both ready-made solutions for the production of greenhouses and manufactures equipment for an individual project.

Automatic cold forming lines are designed by Meer Group design office.

Depending on the characteristics of the metal being processed and the requirements for the manufactured products, our company designs and manufactures equipment that is optimally suited for each Customer.

Any profiling line complies with international standards and can ensure the operation of the plant with any speed.

Specifications

Processed material

cold rolled steel with or without zinc coating

Belt thickness

0,4…2,0 mm

Belt width

40…250 mm

Capacity

300 4-meter parts per hour. Cut with or without line stopping.

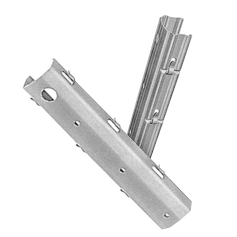

Manufactured products

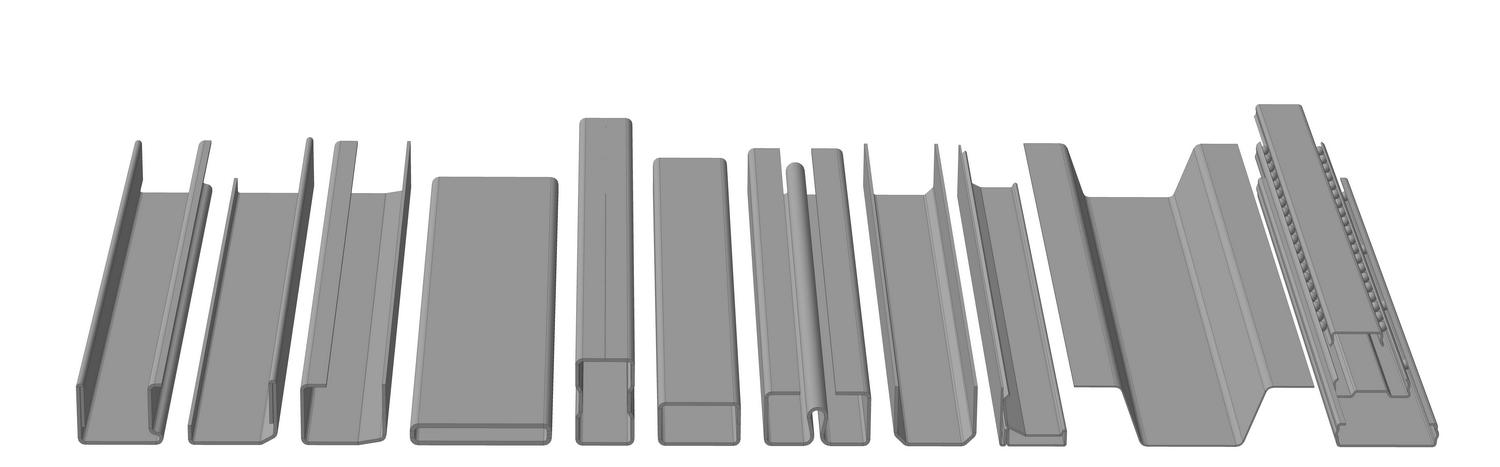

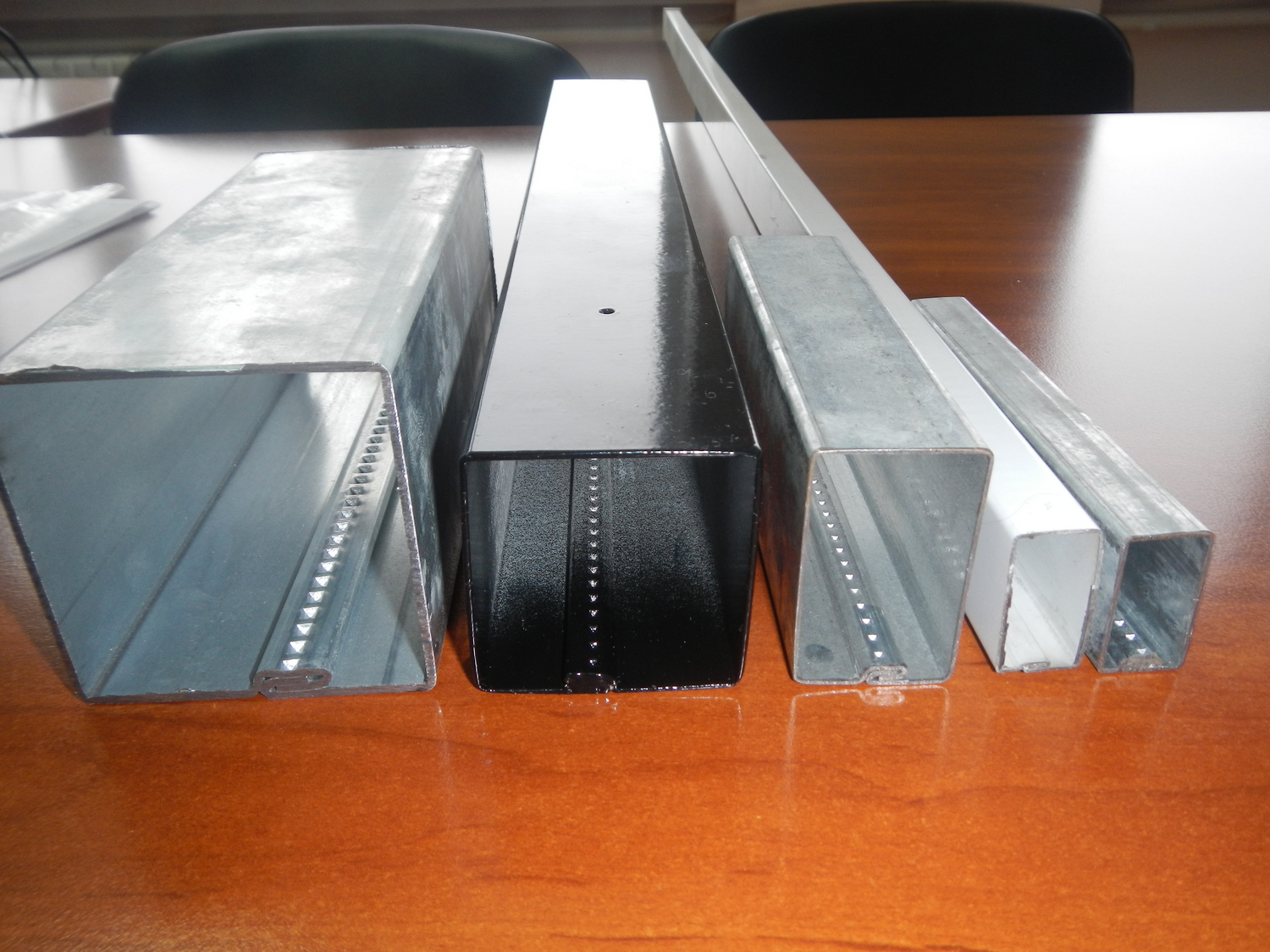

Profiles for the manufacture of greenhouses. The transition from one type of profile to another is carried out by changing the tooling on the line. Manufactured products (profiles) can have a different cross-section and purpose (profiles are closed and not closed).