Elevator systems

Solutions inspired by your ideas and our experience

Equipment

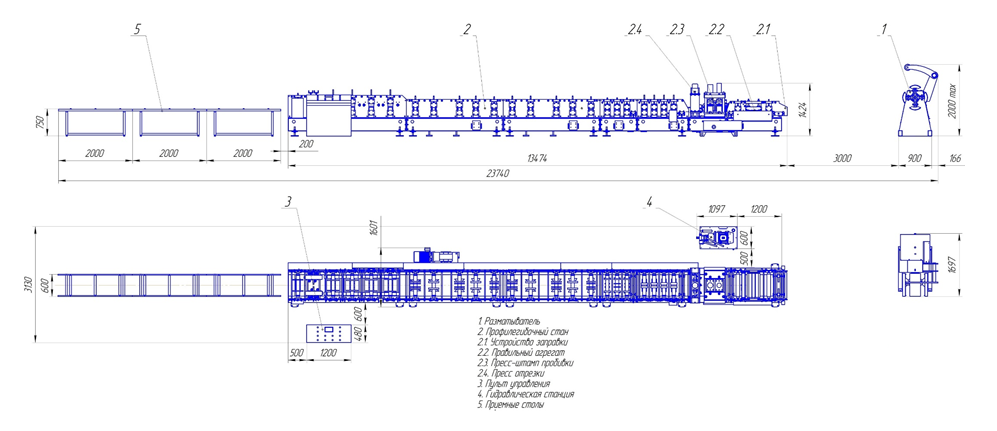

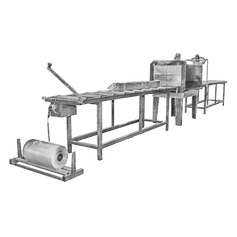

Decoiler

1 pc.

Roll forming mill

1 pc.

Роторные штампы перфорации

1 pc.

Cutting device

1 pc.

Hydraulic station

1 pc.

Reception table

2 pcs.

Control cabinet

1 pc.

Options

- Replaceable perforation blocks;

- Protective film application device;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking by the management of the line.);

- Logistics and packaging.

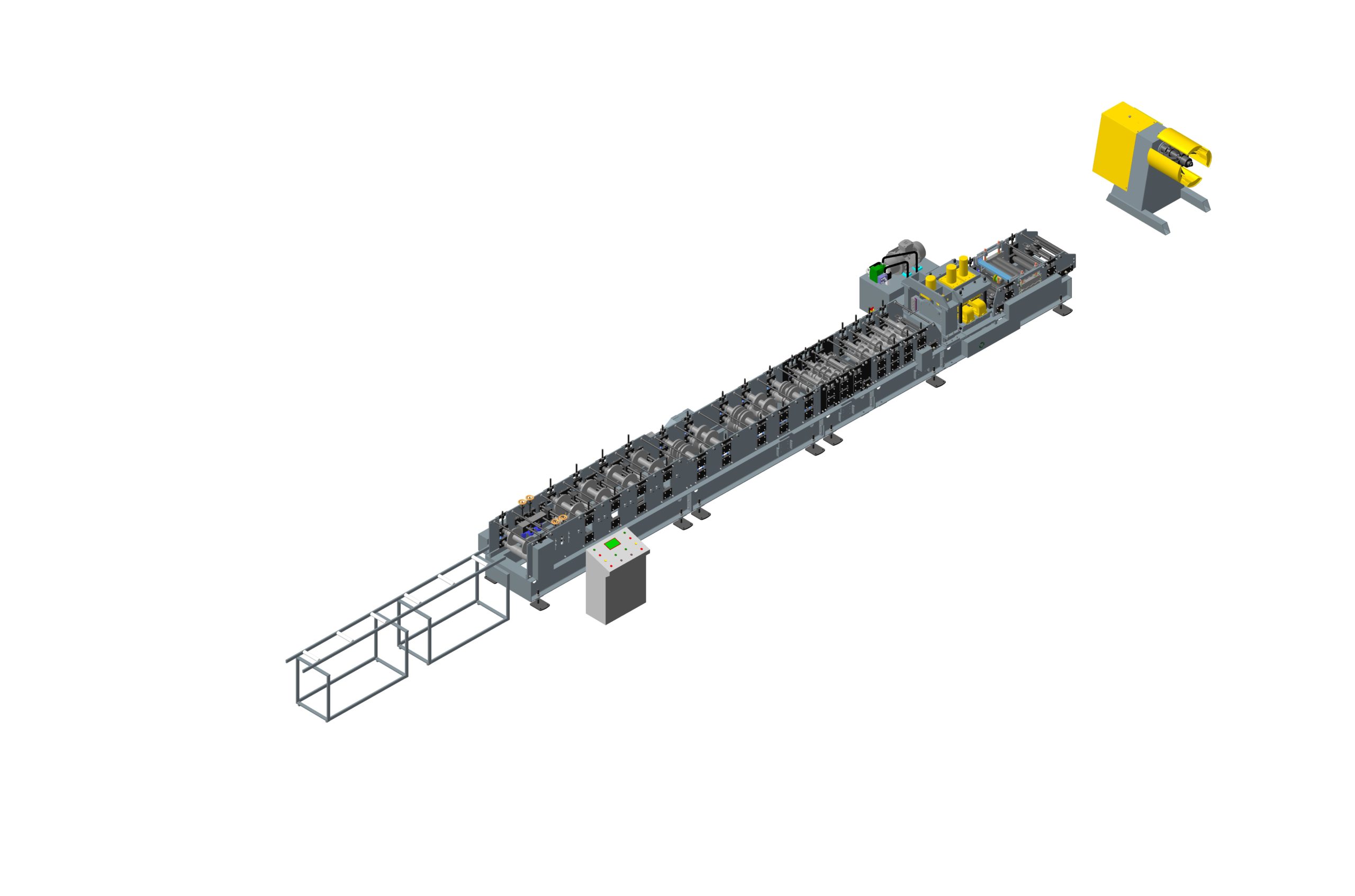

Description of the line

Meer group produces equipment for elevator systems. Profiles are made by rolling/perforating/stamping/cutting off in automatic/semi-automatic mode.

Specifications

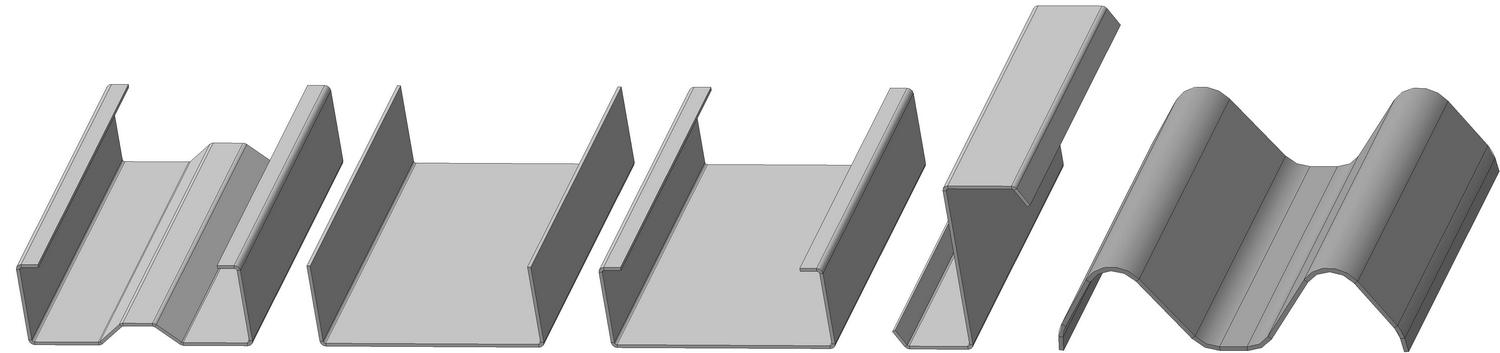

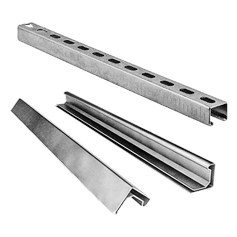

Type of finished profile

According to drawings

Требования к геометрической точности и качеству профиля

Согласно чертежа профиля

Thickness of the processed material

Galvanized steel with yield strength not more than 400 MPa, tensile strength not more than 500 MPa, relative elongation not less than 16%.

Thickness of the processed material, mm

1,5-3,0

Workpiece width, mm, no more

According to the terms of reference

Feeding table

Adjustable in width, with the possibility of installing cheeks at the same distance from the profile axis

Editing block

Driven, installed on the mill

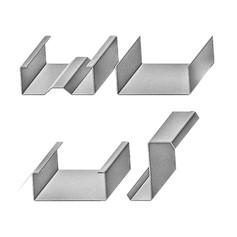

Block of rotary dies for making cuts and bending the profile flange

Block of rotary dies for perforation in profiles

Profiling and dressing unit drive

Chain transmission from a bevel gear motor

Cutting device drive

Rtary stamp die

Profile perforation changeover

Changeover time - no more than 10 minutes.

Line productivity (average, depending on the length of the profile).

20 run. m. / min

Marker

According to request

Safety

Protective screens installed on the mill

Overall dimensions (length x width x height), mm

6200 х 1200 х 1750

Weight, kg

5000