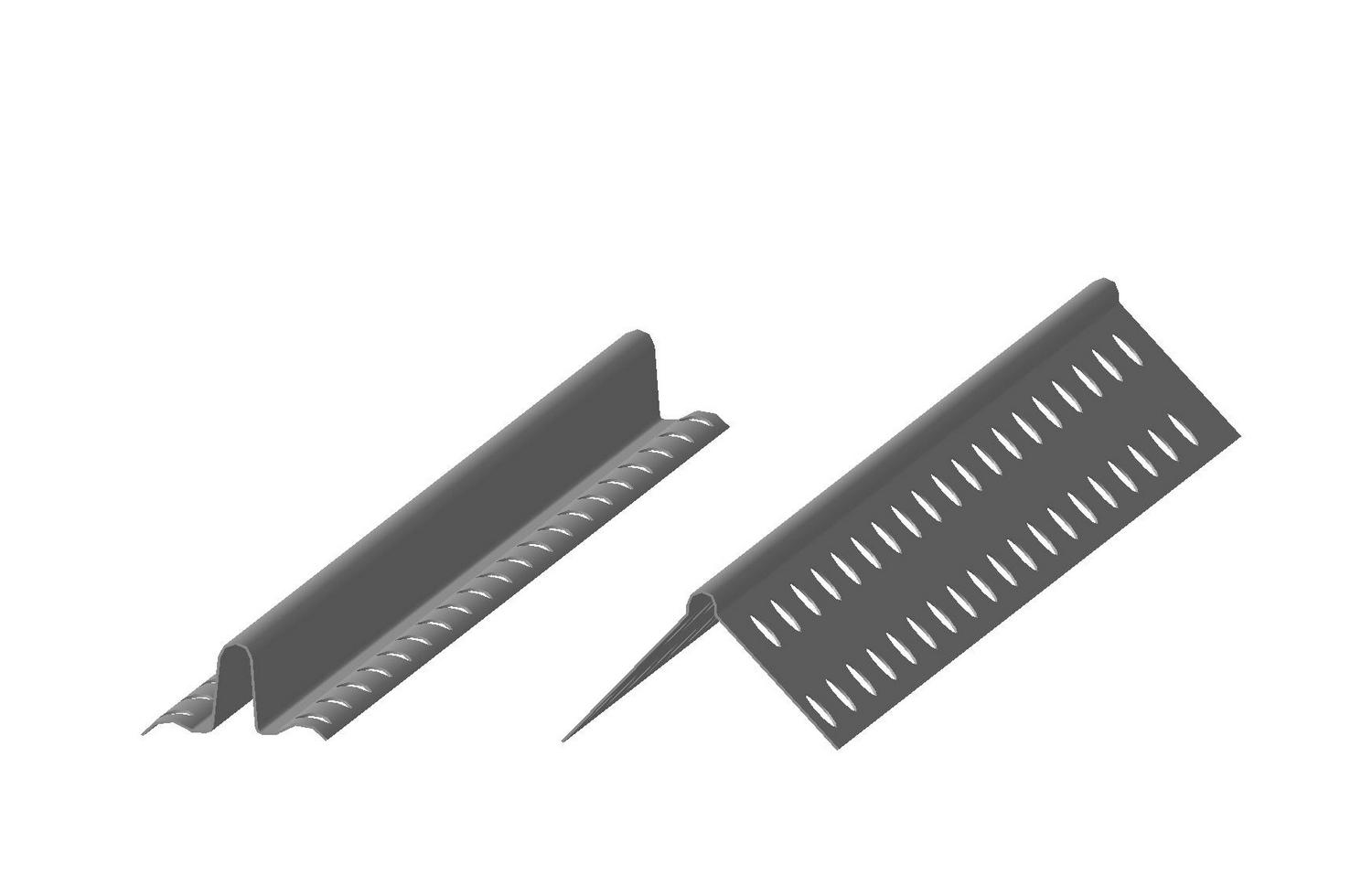

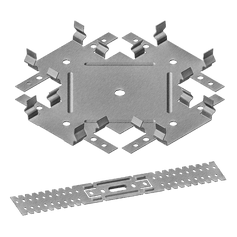

Beacons of the corner

Solutions inspired by your ideas and our experience

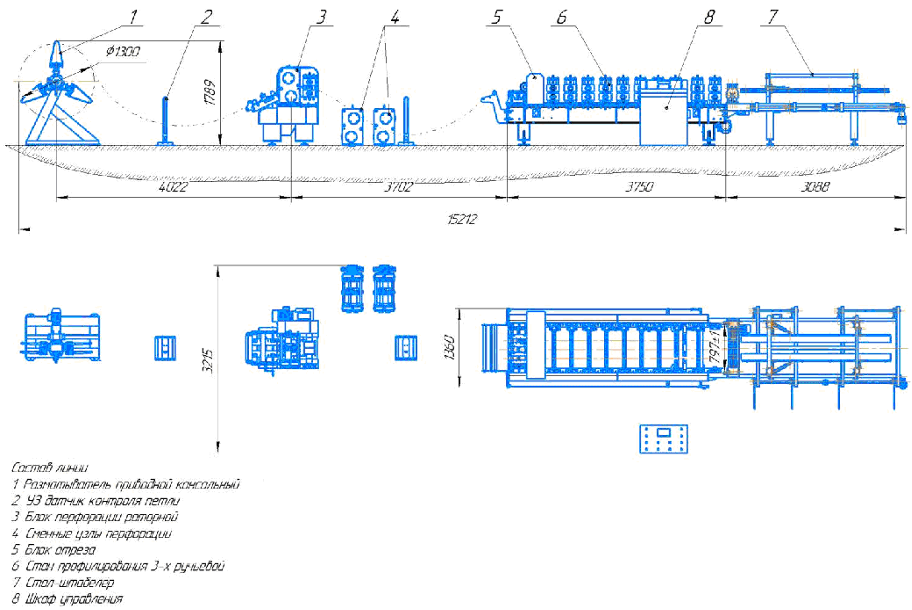

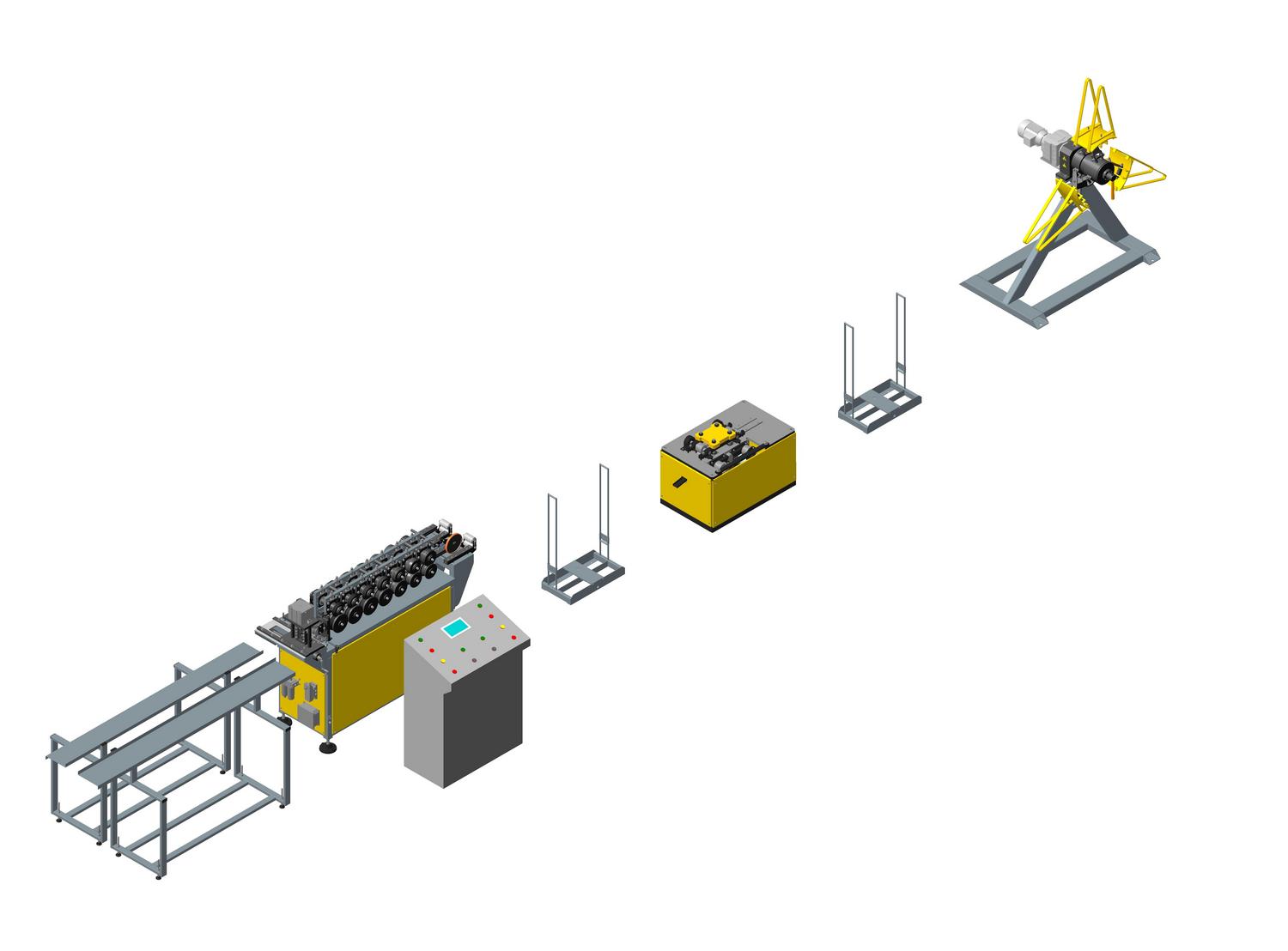

Equipment

Decoiler

1 pc;

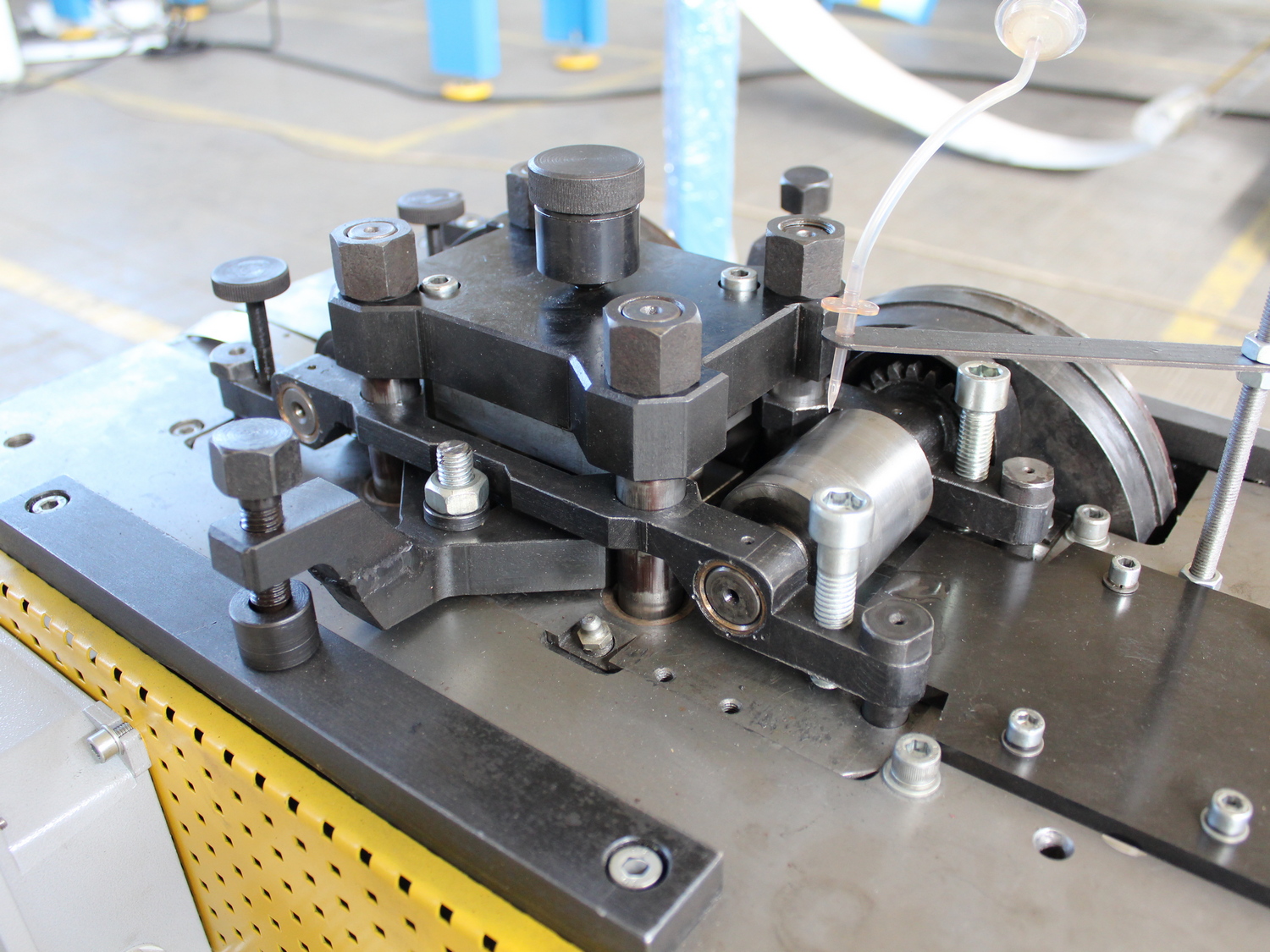

Press stamp or rotary stamp

1 pc;

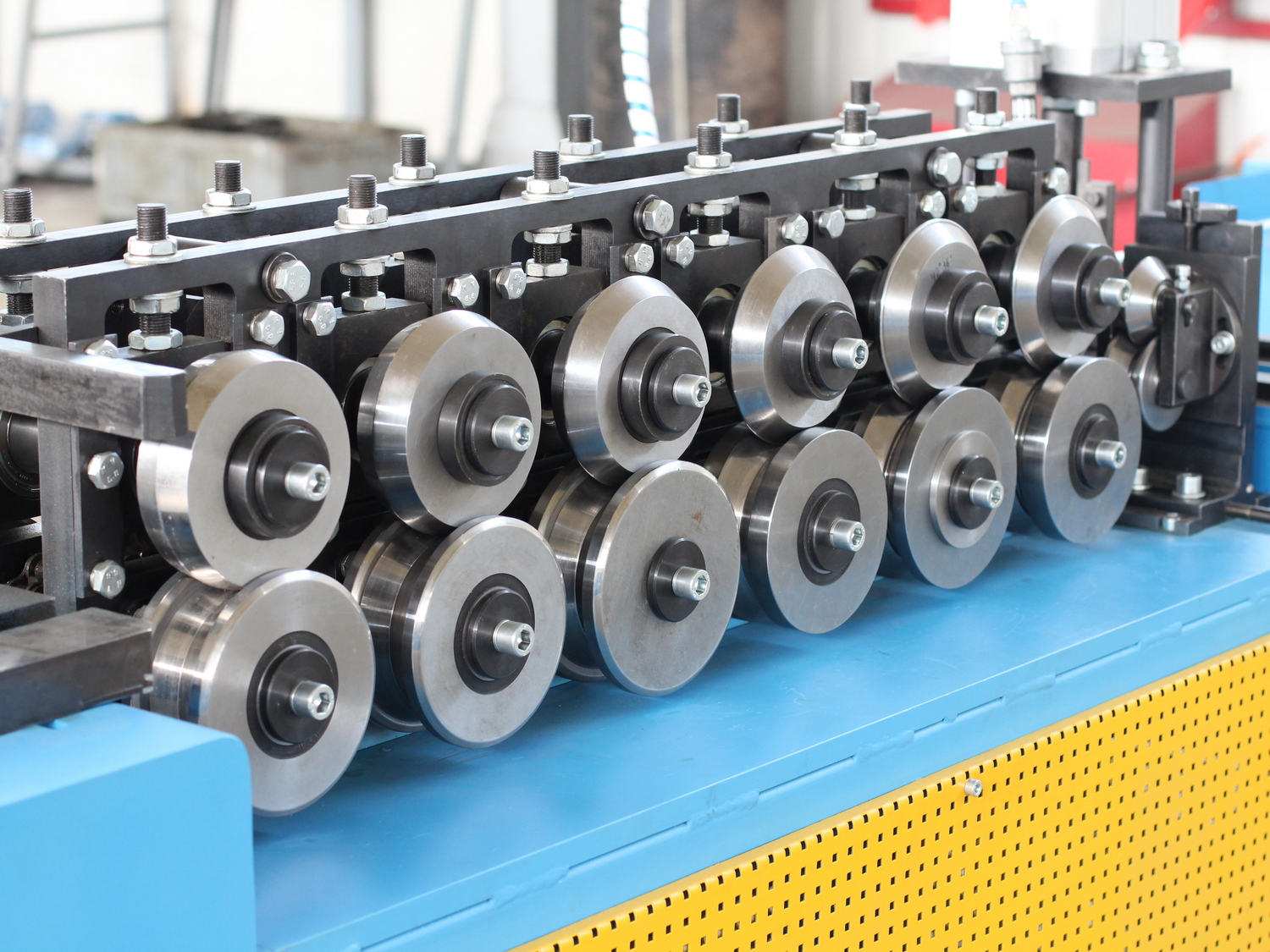

Roll forming mill

1 pc;

Cutting device

1 pc;

Receiving table

2 pcs;

Control cabinet

1 pc;

Options

- Replaceable perforation complexes;

- Stamps – duplicators;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remote access, statistics. Tracking of line work by the management);

- Logistics and packaging

Description of the line

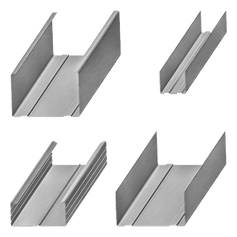

The line is designed for the manufacture of plaster beacons and filler corners of various types from galvanized steel 0.4-0.6 mm, as well as from aluminum with a thickness of 0.3-0.5 mm.

Specifications

Processed material

Galvanized sheet steel (DC01, DC04, used in cold profiling), aluminium

Thickness of the processed material

0.4-0.6 mm (Plaster beacon), 0.3-0.5 mm (corner beads)

Workpiece width

According to drawings

Profiling speed

80 run. m./ min.

Accuracy of cutting

± 5 mm

Roll Forming Mill Type

Console / rack-mount

Press die type

Electromechanical

Work mode

Semi-automatic

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming mill, equipped with a frequency converter

Operating personnel

2 persons