Welded pipes

Solutions inspired by your ideas and our experience

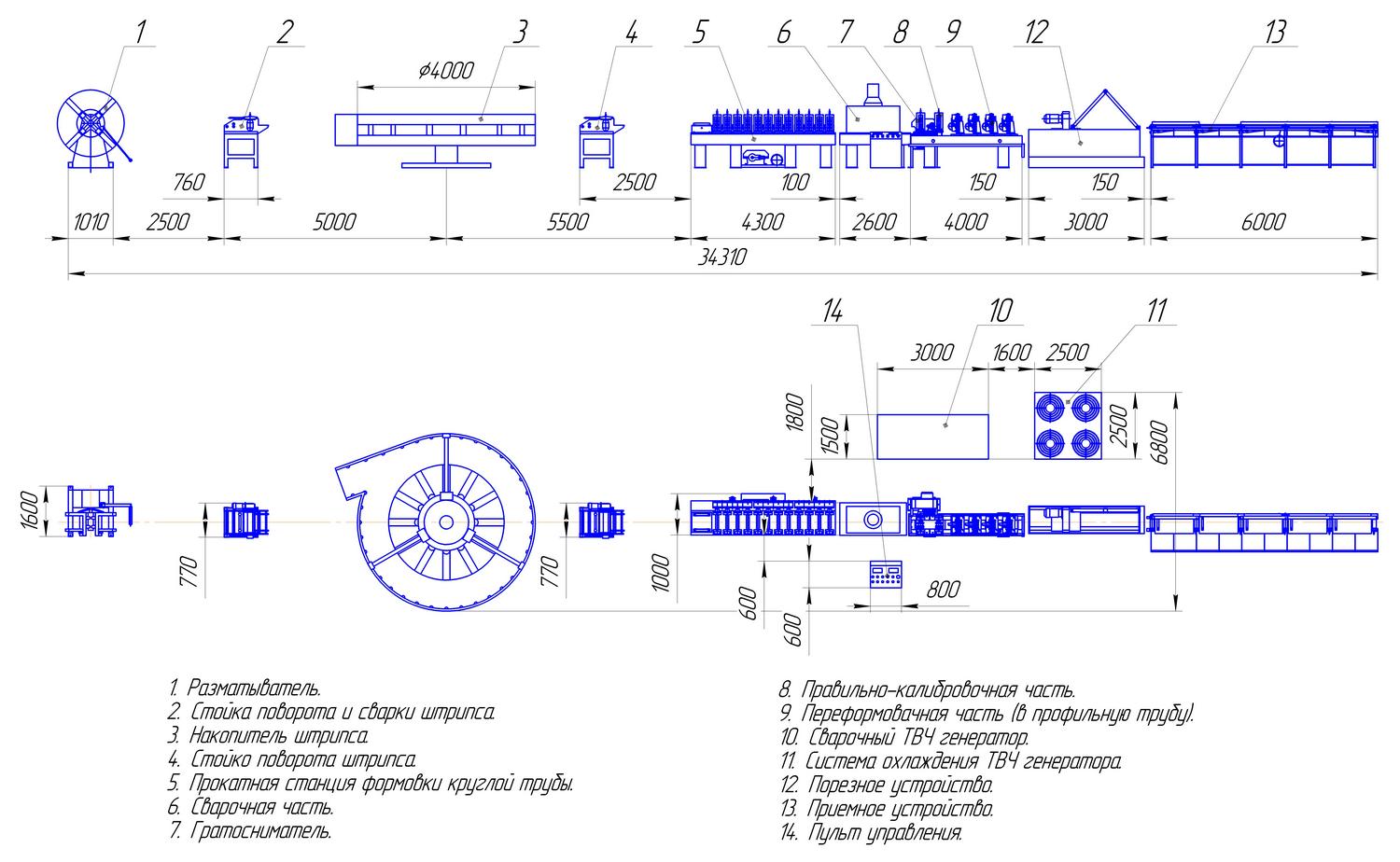

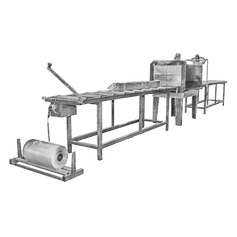

Equipment

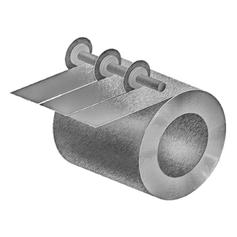

Decoiler

1 pc;

Strip butt welding unit

1 pc;

Strip accumulator (storage)

1 pc;

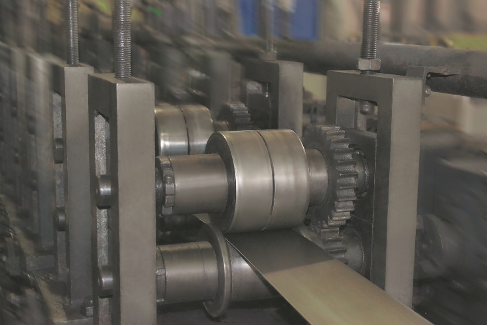

Mill for forming, welding, sizing, reforming into a shaped tube, with a cooling and lubricating fluid system

1 pc;

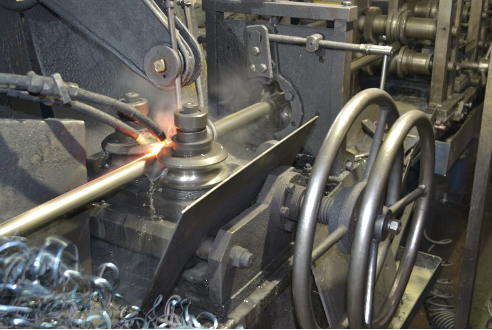

High frequency spot welding generator

1 pc;

Cutting device

1 pc;

Pick-up table - ejector

1 pc;

Control cabinet

1 pc;

Options

- – We offer rolling tool sets on separate shafts with bearing housings. Changeover time from one pipe size to another is approx. 90 minutes;

– Fences, sensors, cameras of critical areas, monitors;

– Tracking module (Operation, maintenance, simple, remote access, statistics. Tracking by the management of the line.);

– Logistics and packaging;

– Lamp high frequency spot welding generator

Description of the line

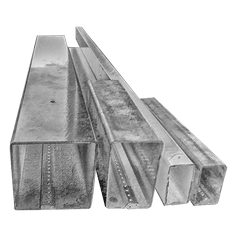

The line is designed for the production of longitudinal welded pipes with a diameter of 15 to 38 mm with a wall thickness of 0.8 to 1.8 mm, as well as pipes with a diameter of 42 to 127 mm with a wall thickness of 1.5 to 3.0 mm.

The line provides for the possibility of reforming round pipes into profile ones – square and rectangular.

Specifications

High frequency spot welding generator

100/300 kWt

Power consumption

up to 180/750 kWt

Capacity of the line

up to 1000 ton/month

Rolling - welding speed

up to 6 m/min.

The line is mounted on the site

8,5×50 m

Pipeline operators

4 people