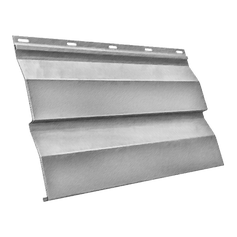

Seam roof

Solutions inspired by your ideas and our experience

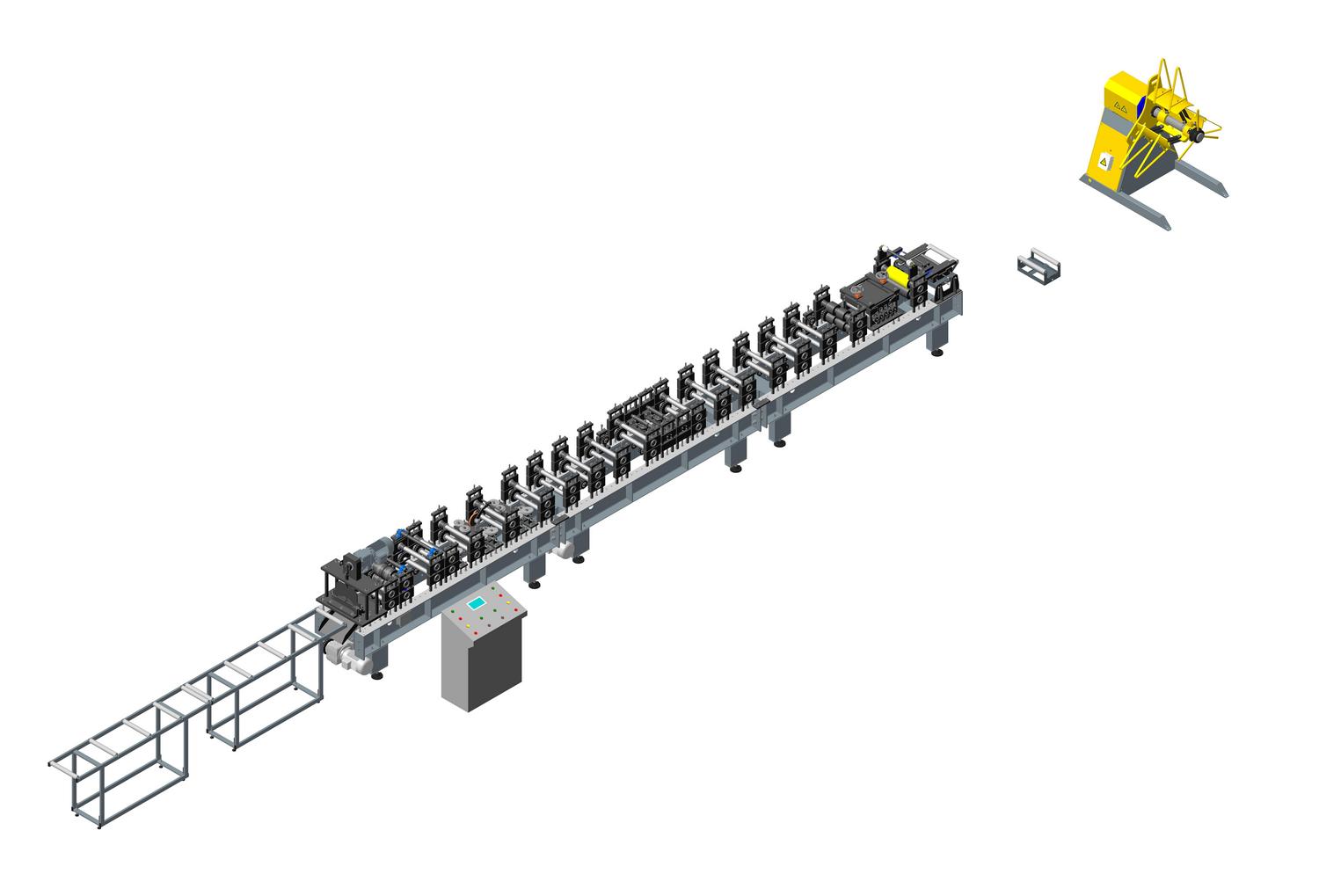

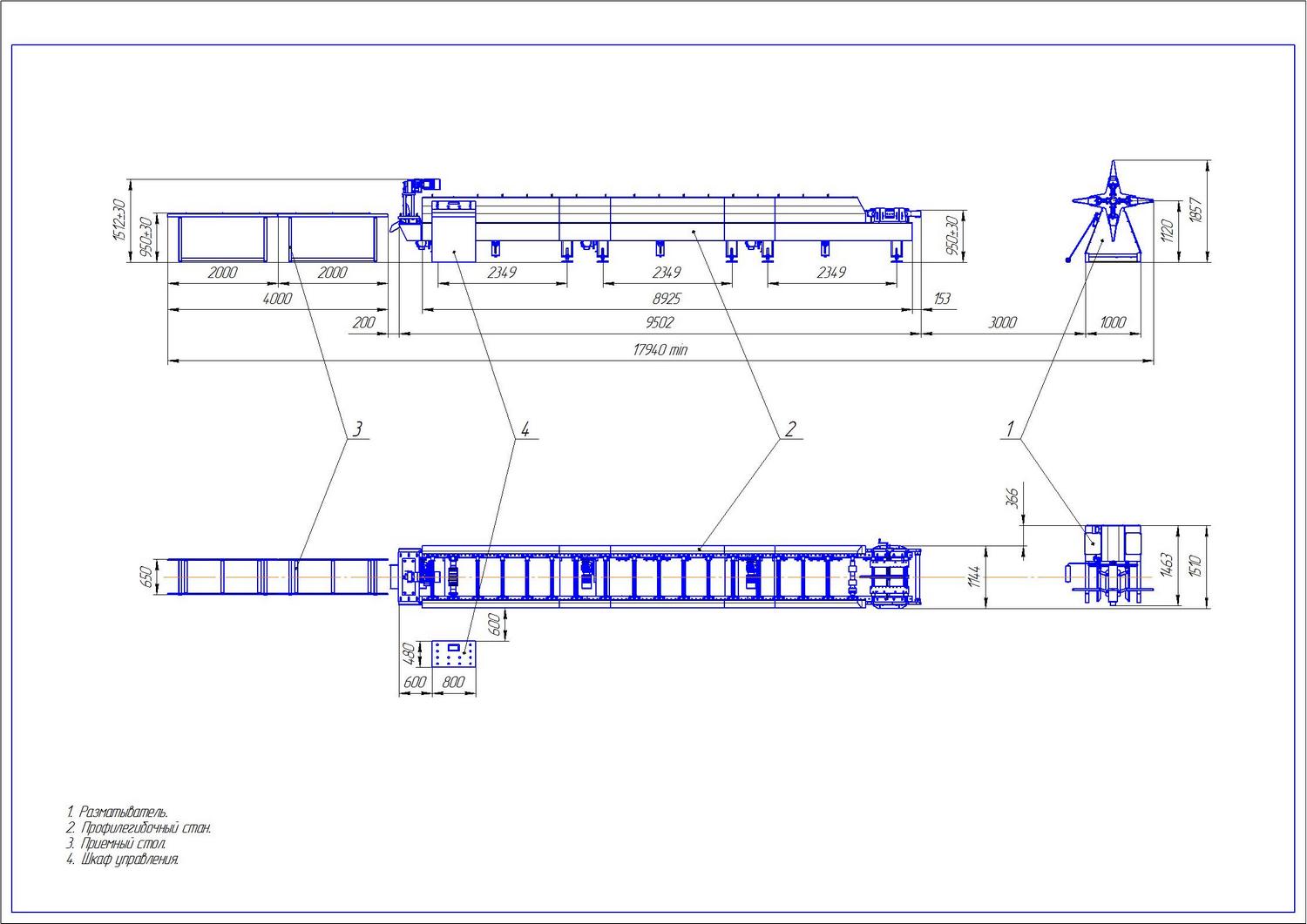

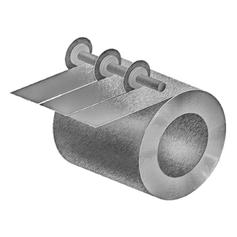

Equipment

Unwinder

1 pc;

Punching/ Punching press die

1 pc.

Roll forming mill

1 pc;

Cutting device

1 pc;

Pick-up table

1 pc;

Control cabinet

1 pc

Options

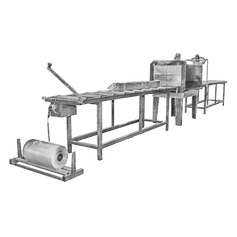

Film application device;

Fences, sensors, cameras of critical areas, monitors;

Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking by the management of the line.);

Logistics and packaging;

ОПИСАНИЕ ЛИНИИ:

The Meer Group company manufactures equipment for different types of seam roofing (Standing single seam, standing double seam, recumbent single seam, recumbent double seam, corner seam is a type of seam located not on the plane, but on the corner of the parts to be joined), according to the needs and developments customers.

We manufacture equipment with different locks and knurls.

Specifications

Processed material

Galvanized sheet steel in accordance with GOST 14918 with protective and decorative paint and varnish coating

Thickness of processed material

0,4-0,6 mm

Blank width

According to sketches

Profiling speed

25 running meters/min

Cutting precision

± 5 mm

Type of profile bending mill

Rack

Work mode

Semi-automatic

Maximum length of the profile received by the pick-up table

4000 mm

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming mill, equipped with a frequency converter

Operating personnel

2 persons