Cable channels

Solutions inspired by your ideas and our experience

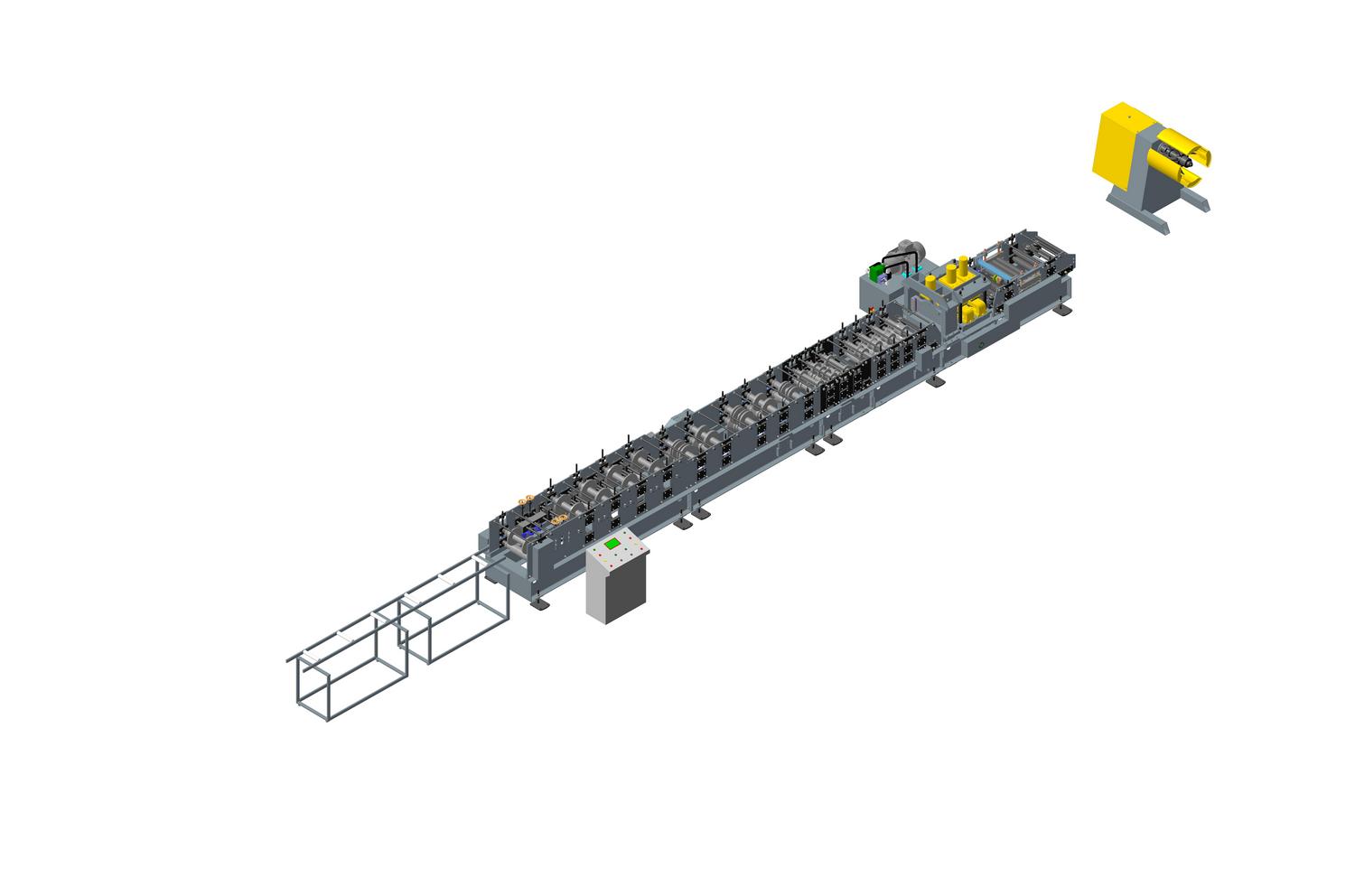

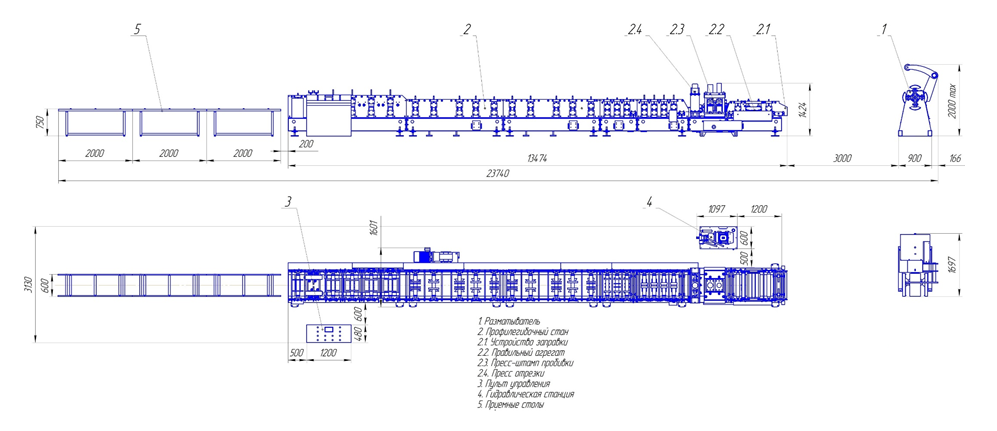

Equipment

Decoiler

1 pc;

Correct device

1 pc;

Roll forming mill

1 pc;

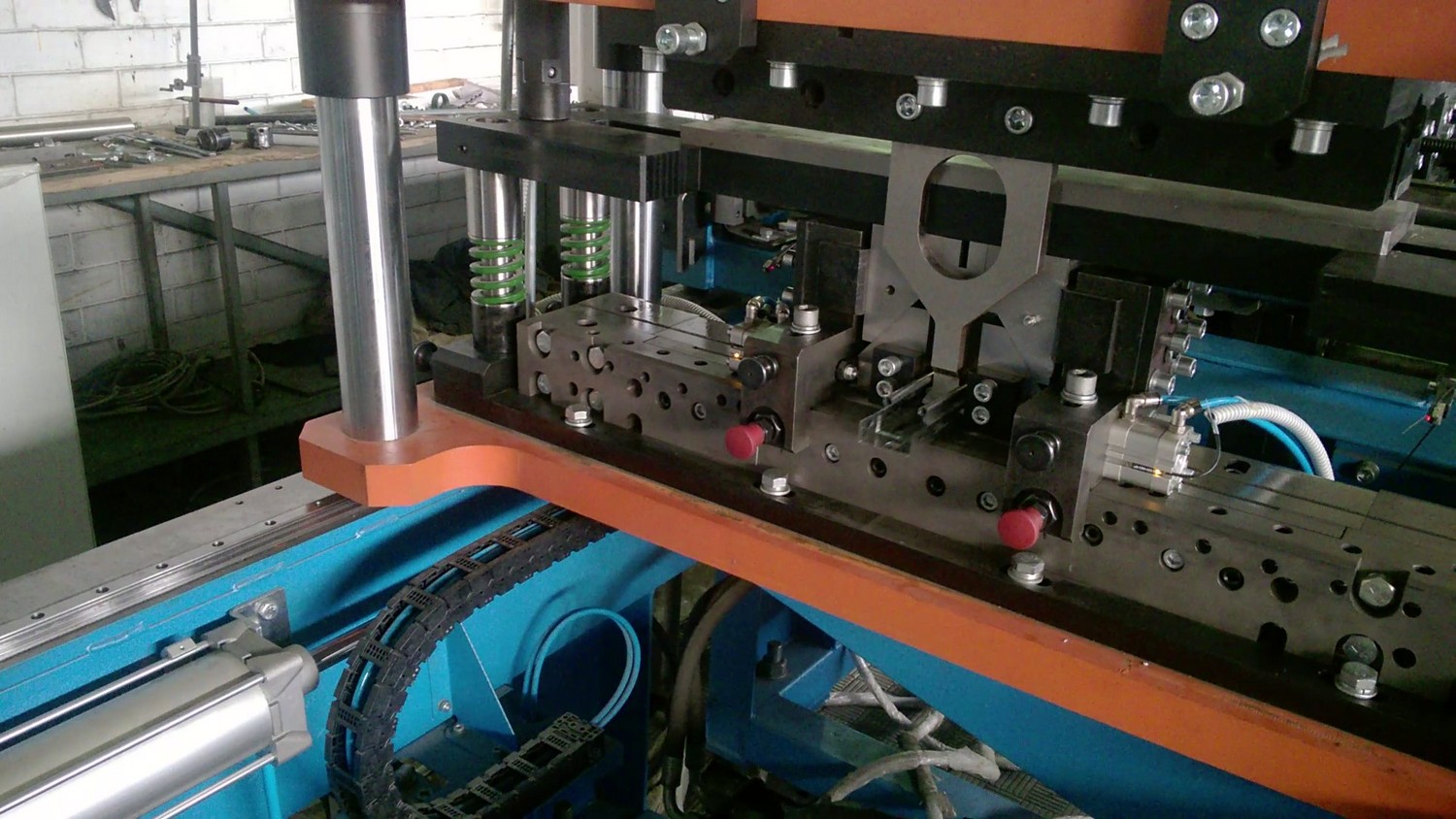

Press-stamp

1 pc;

Cutting device

1 pc;h

Hydraulic station

1 pc;

Receiving table

1 pc;

Control cabinet

1 pc;

Stamping equipment

Options

- Replaceable die equipment;

- Stamps – duplicators;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remotĕ access, statistics. Tracking by the management of the line.);

- Logistics and packaging.

Additioonal information

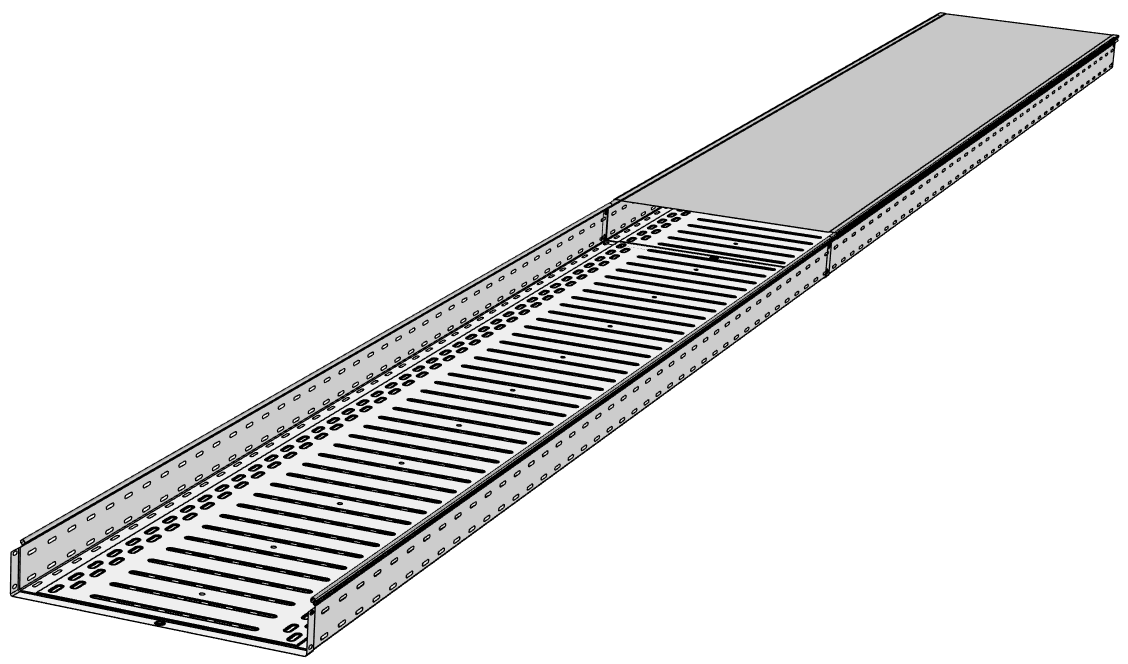

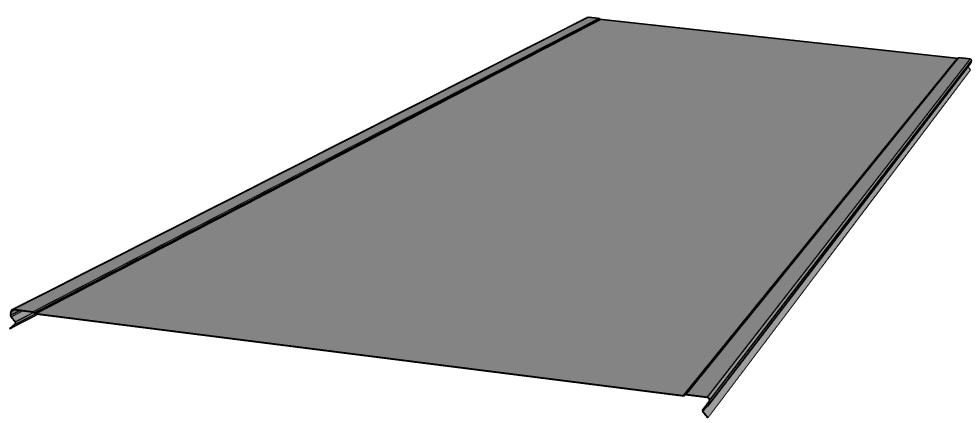

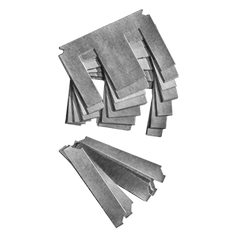

Meer Group manufactures reliable and durable equipment for its customers, which carries out automatic rolling of cable channels and covers for them, perforation, and cutting.

The production efficiency allows our customers to adjust it according to the size of the finished product.

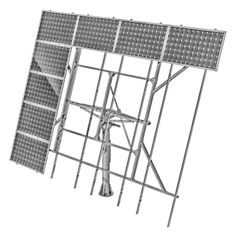

The size of the finished product varies according to the needs of the Buyer. The products are widely used for laying power cables, telephone and other wires to prevent damage. In addition, the finished product has fire-resistant properties.

Specifications

Mill type

Cassette (one set of cassettes for the perforated tray, the second set of cassettes for the cover of the tray). Resizable in width.

Type of processed material

Galvanized steel, stainless steel

Thickness of the processed material, mm

0.55-1.5 (0.55-0.8 for stainless steel)

Workpiece width, mm

no more than 850

Maximum profile height, mm

no more than 100

Rack type

Adjustable in width to adapt to different widths of the perforated tray or tray cover

Profiling speed, linear m / min

no more than 20

Number of profiling drive stands, pcs., not more *

19

Mill drive *

Chain transmission from a coaxial gear motor Motovario (Italy) or an analogue of European production

Installed power of the mill drive, kW *

15

Press stamp cut-off

Flying four-column press, with a set of replaceable dies

Overall dimensions of the mill (length x width x height), mm *

9880 х 1490 х 1460

Mill weight, kg *

9000