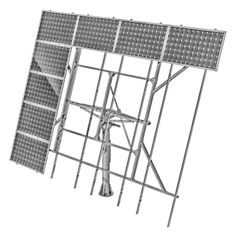

Transformer plates

Solutions inspired by your ideas and our experience

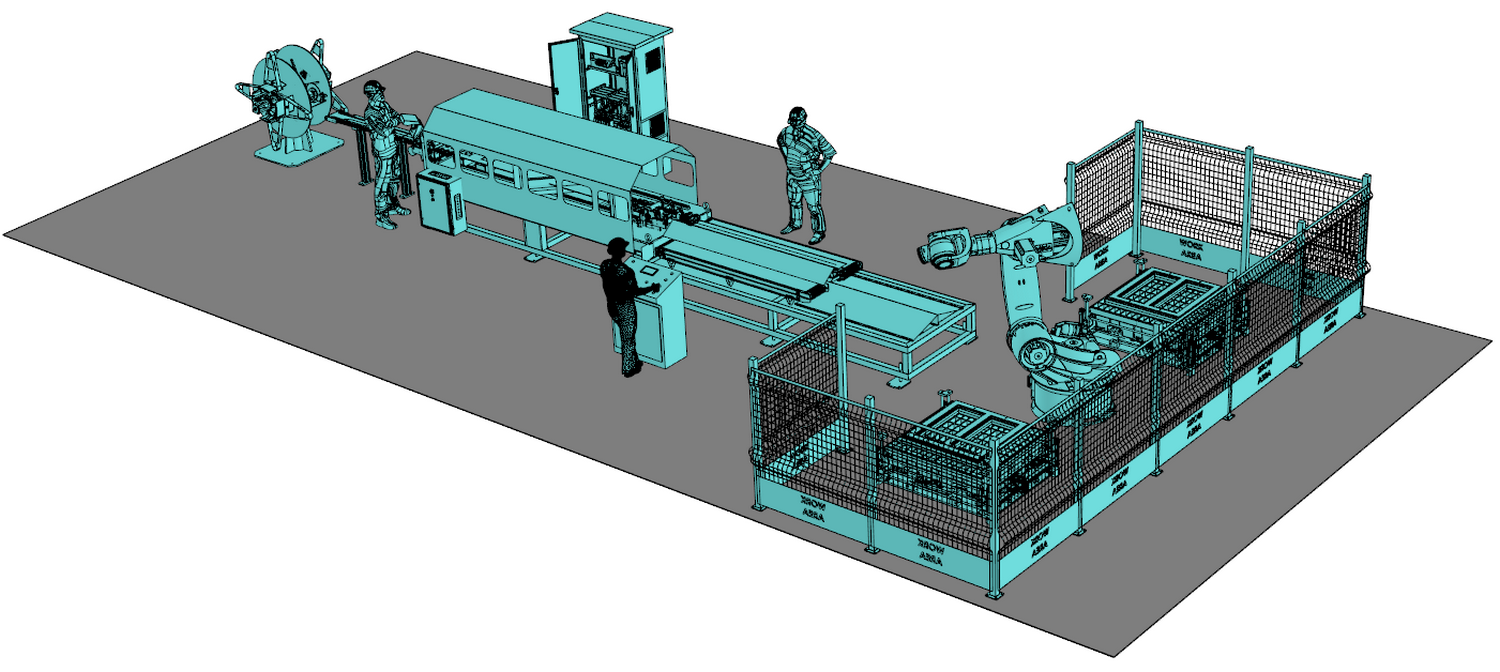

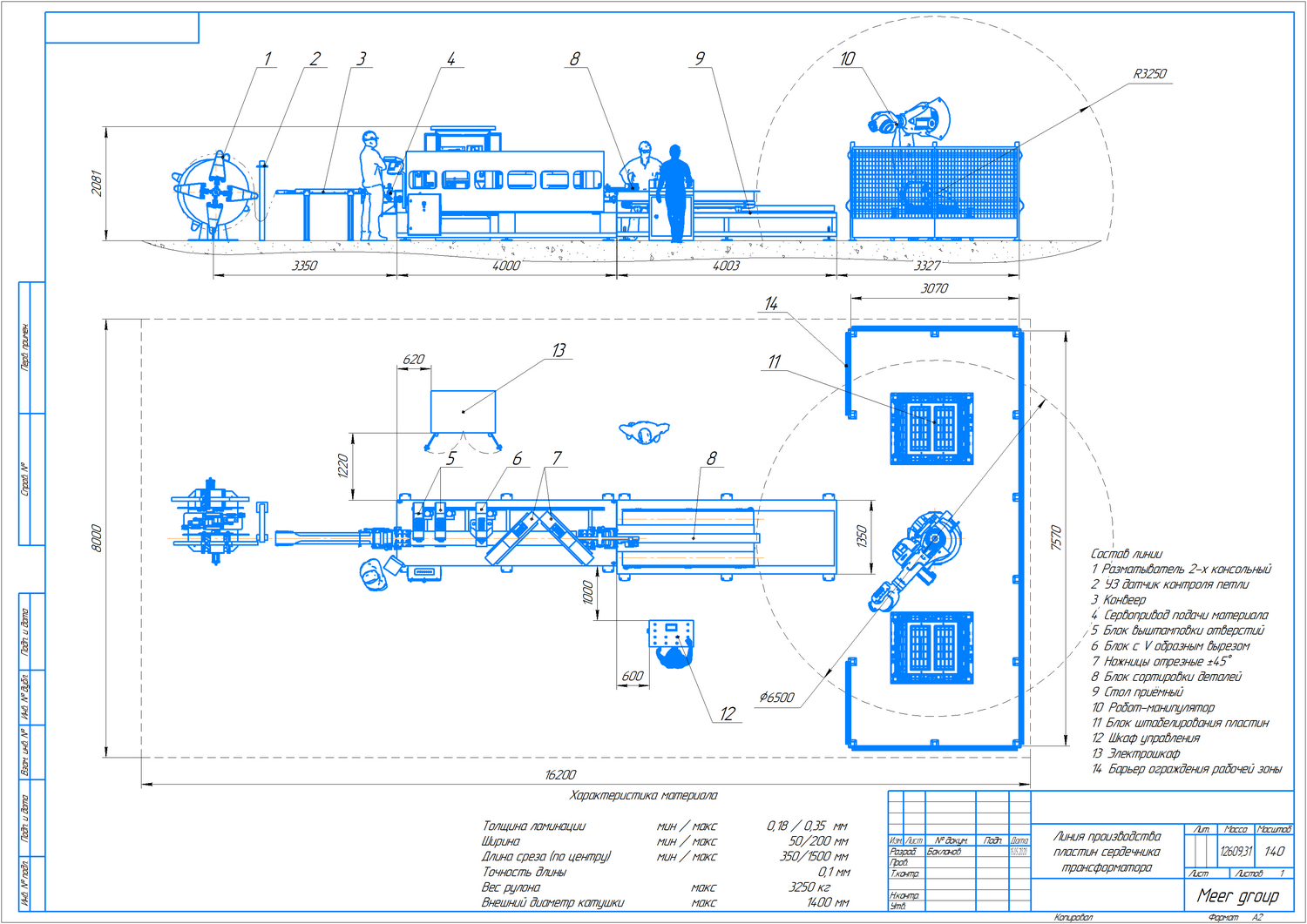

Equipment

Decoiler

1 pc.

Press stamp

1 pc.

Roll forming mill

1 pc.

Cutting device

1 pc.

Receiving container

1 pc.

Control cabinet

1pc.

Options

- Robot manipulator;

- Replaceable stamps understudies;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking of work by the management);

- Logistics and packaging

Description of the line

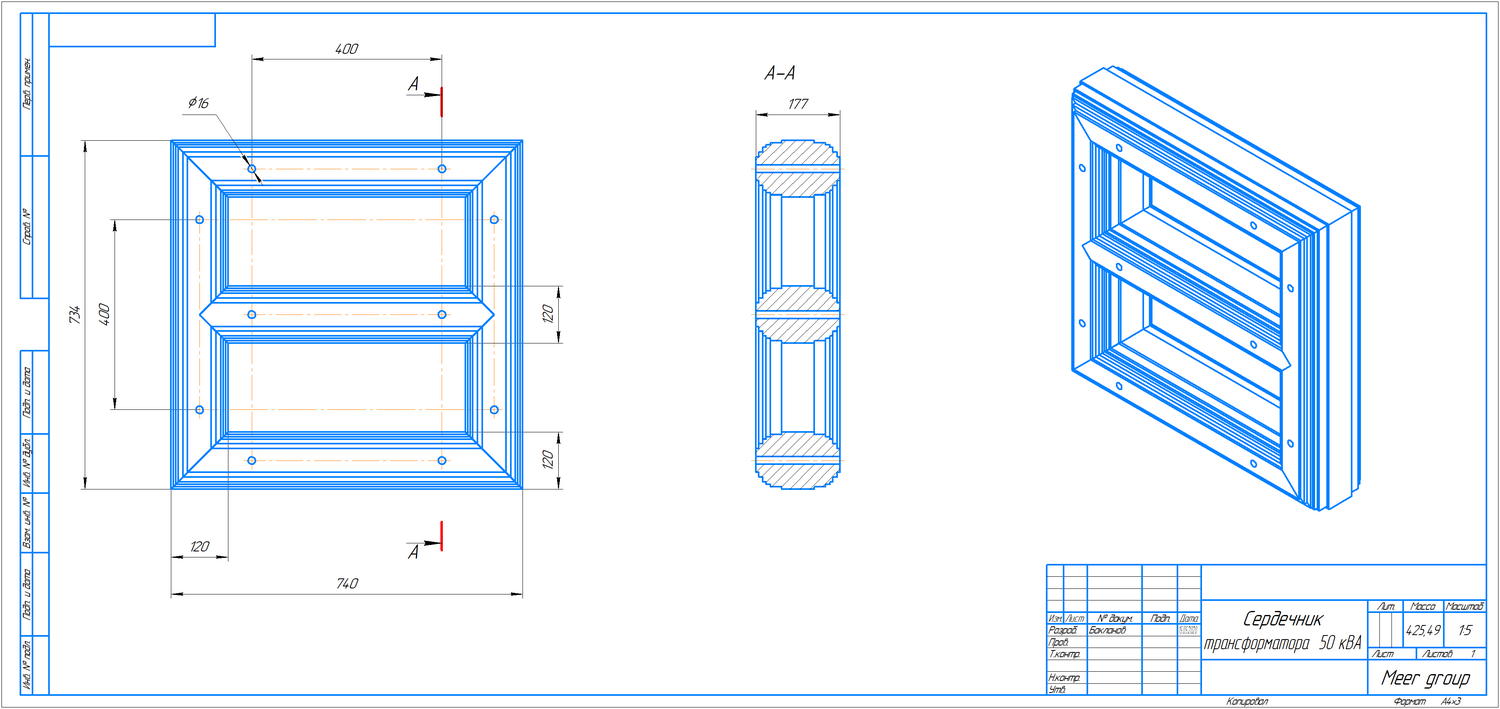

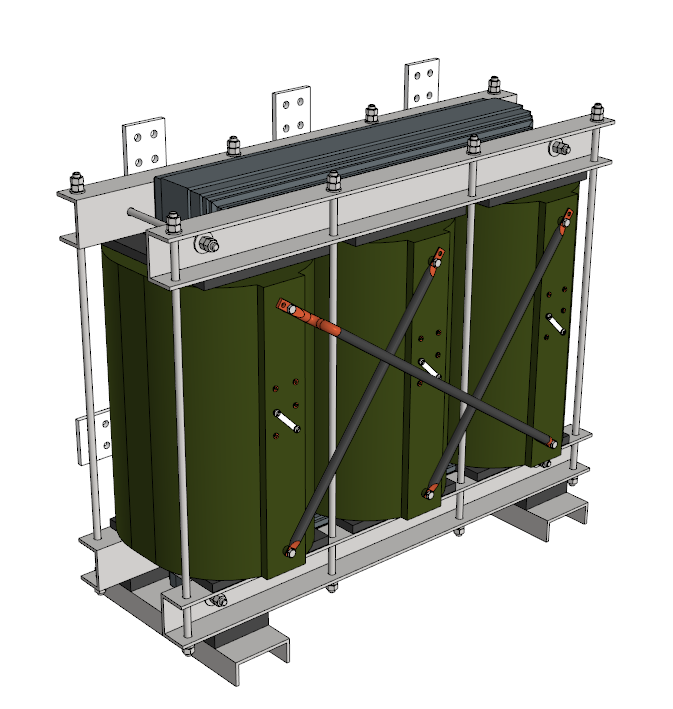

The line is designed for the manufacture of rolled thin sheet electrical steel (0.18 … 0.35 mm) of core plates for a power transformer from 50 to 2500 kW, followed by assembly of the core itself on stands in automatic mode using a robotic arm.

Specifications

Line operation mode

Semi-automatic

Decoiler type

2-console, driven

Decoiler load capacity

1,5 т.

Material

Electrotechnical rolled anisotropic steel

Workpiece width

50-200 mm

Workpiece thickness

0,18 … 0,35 mm.

Profile length (along the central axis)

Minimum - 350 mm Maximum - 1500 mm

performance, not less

80 м. run. m/ min

Accuracy standards for profile length

±0,1 mm.

Installed capacity of the mill, not more than

16 kWt

Mill drive

Electromechanical

Drive for punching and cutting stamps

Electromechanical

Voltage

380 V

Power frequency

50 Hz

Control cabinet

Provides automatic operation of the line after filling the line with material, equipped with a frequency converter and CNC

Overall dimensions

16200x8000x4100

Weight

12700 kg

Operating personnel

1-2 persons