Solar systems

Solutions inspired by your ideas and our experience

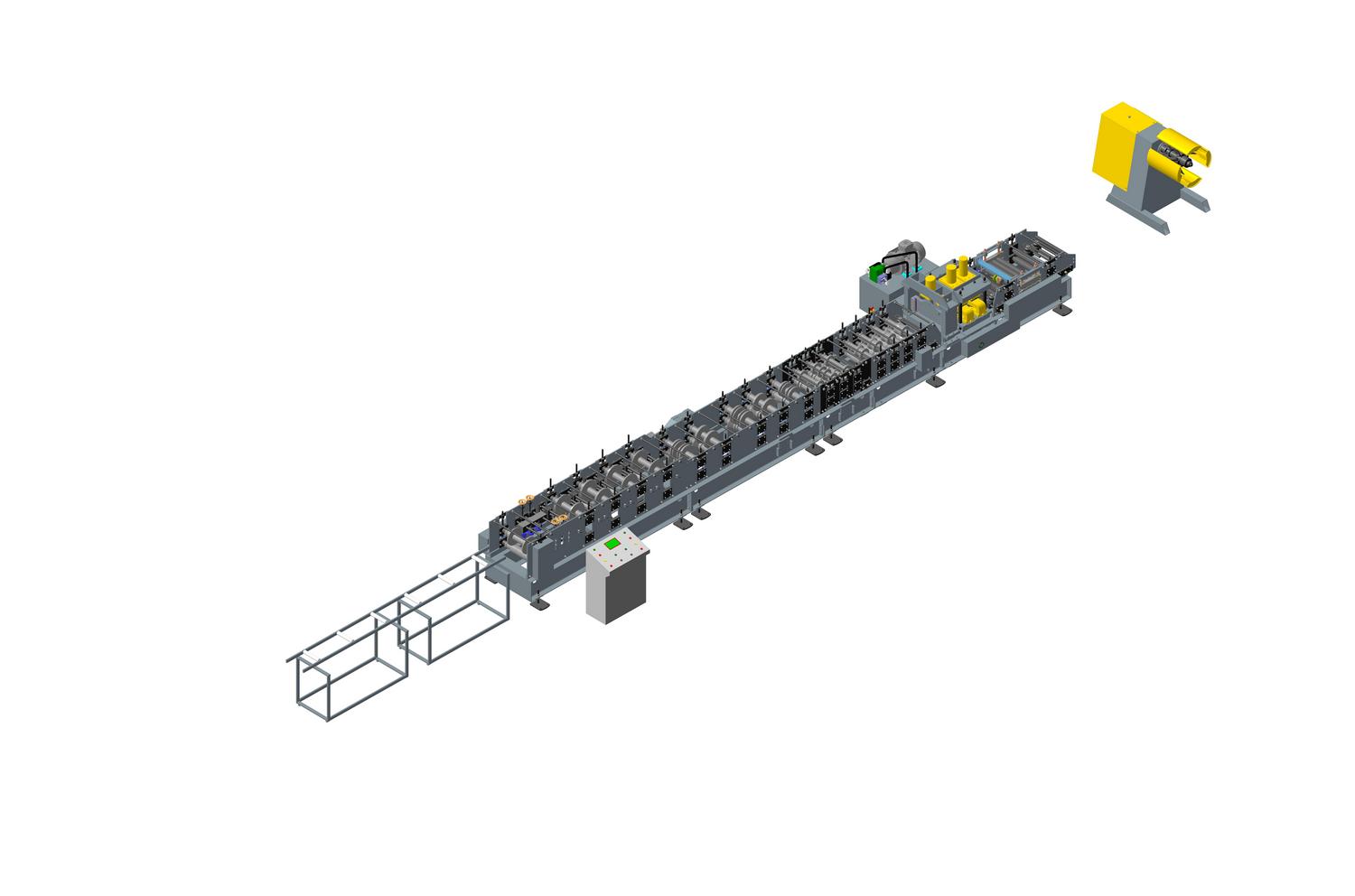

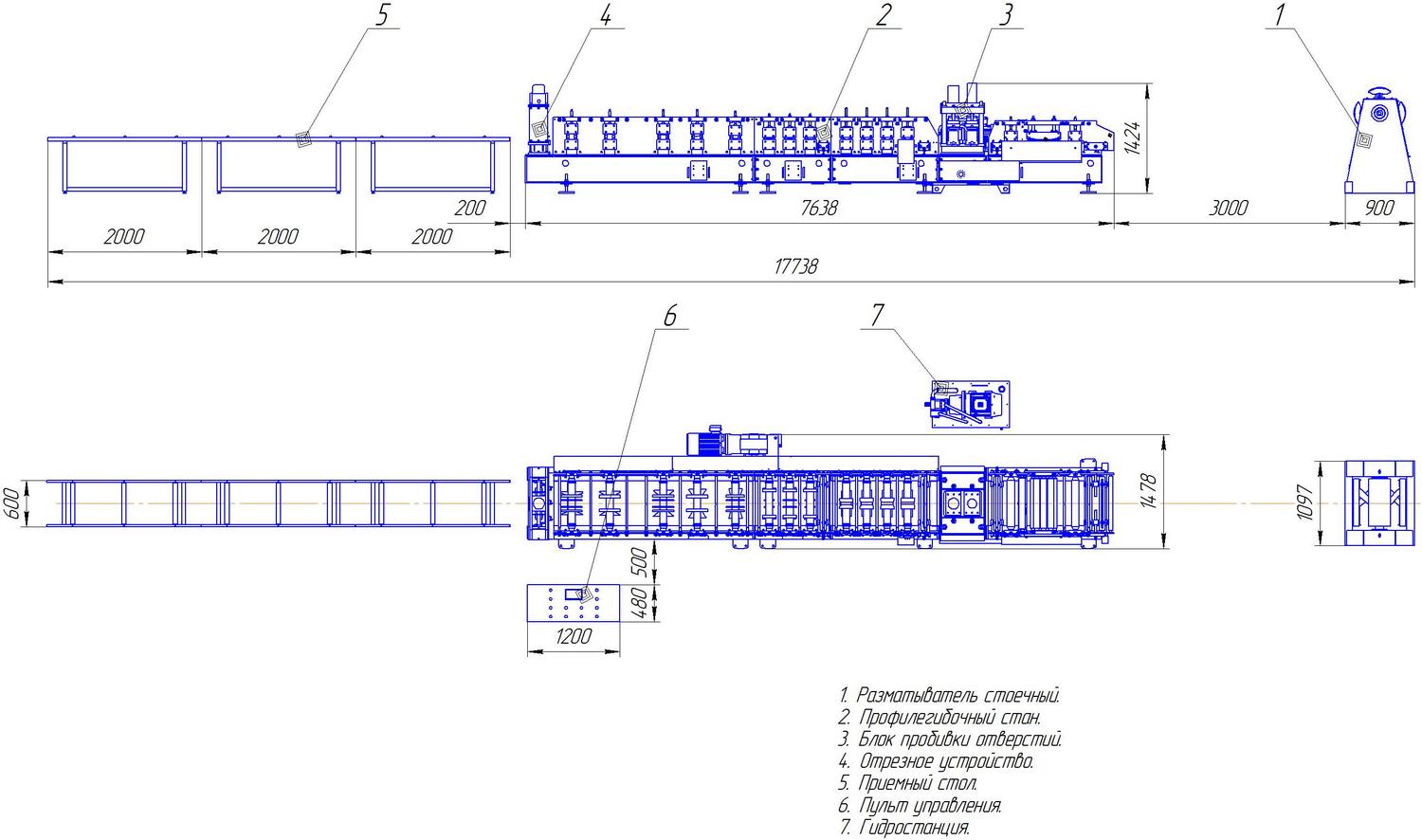

Equipment

Decoiler

1 pc.

Roll forming mill

1 pc.

Cutting device

1 pc.

Receiving table

2 pcs.

Control cabinet

1 pc.

Options

- Profile perforation device;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking by the management of the line.);

- Logistics and packaging.

Description of the line

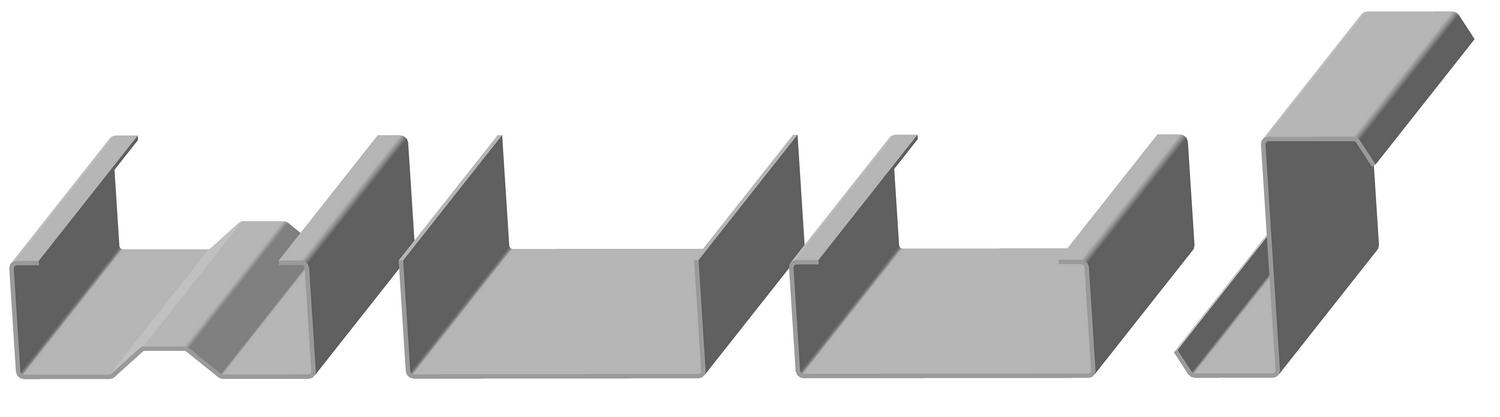

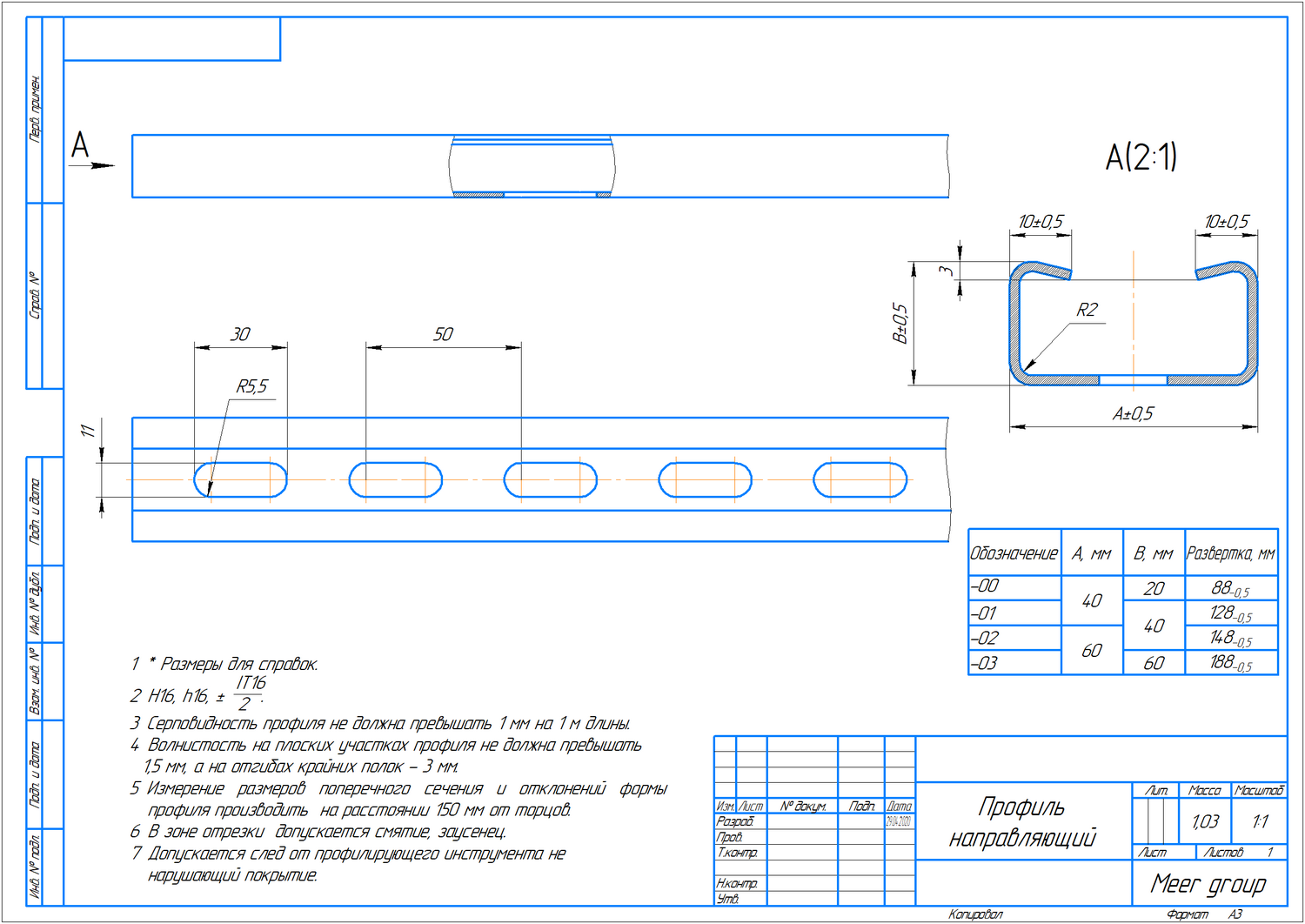

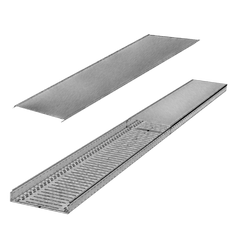

The lines are designed for the production of profiles from which a frame is assembled on which solar panels are mounted from sheet steel with a thickness of 1.0 to 4.0 mm.

Specifications

Processed material

thin-sheet rolled products with a protective and decorative paint coating applied on galvanized steel (steel grades DC01, DC04 with a yield strength of at least 230 MPa, a tensile strength of up to 490 MPa, a relative elongation of at least 22%) or grade DX51D + Z (with a yield strength not less than 230 MPa, tensile strength up to 490 MPa, relative elongation not less than 22%)

Thickness of the processed material

0,3-0,5 mm

Workpiece width

According to drawings

Profiling speed

25 run. m. / min

Cut-off accuracy

± 2mm

Roll Forming mill type

Rack

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming machine, equipped with a frequency converter and CNC

Operation staff

1-2 persons