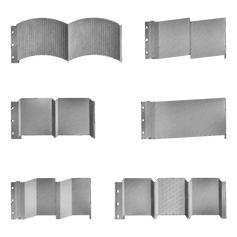

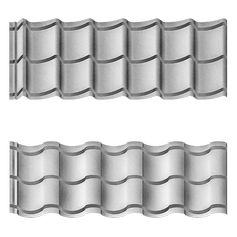

Linear panels

Solutions inspired by your ideas and our experience

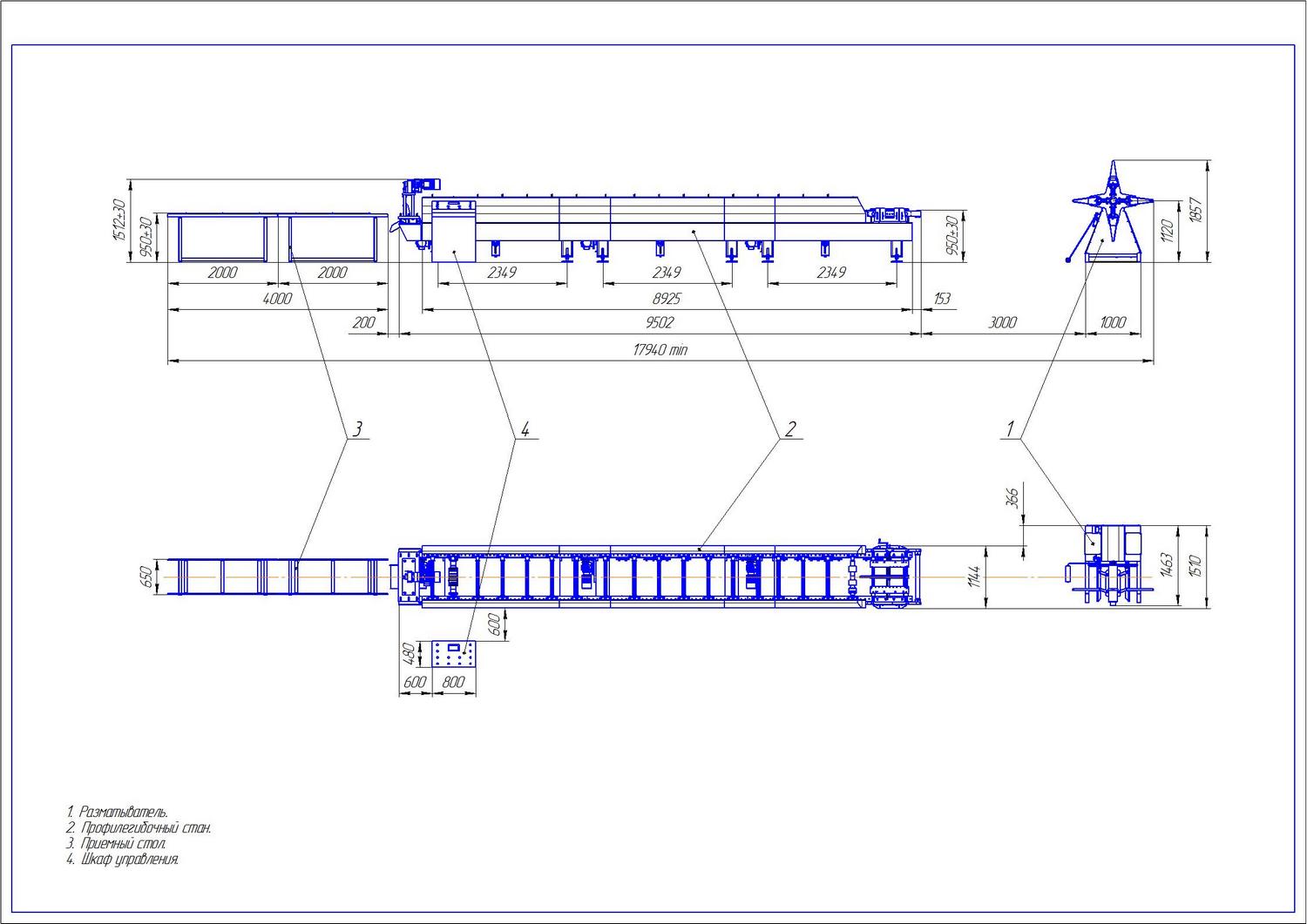

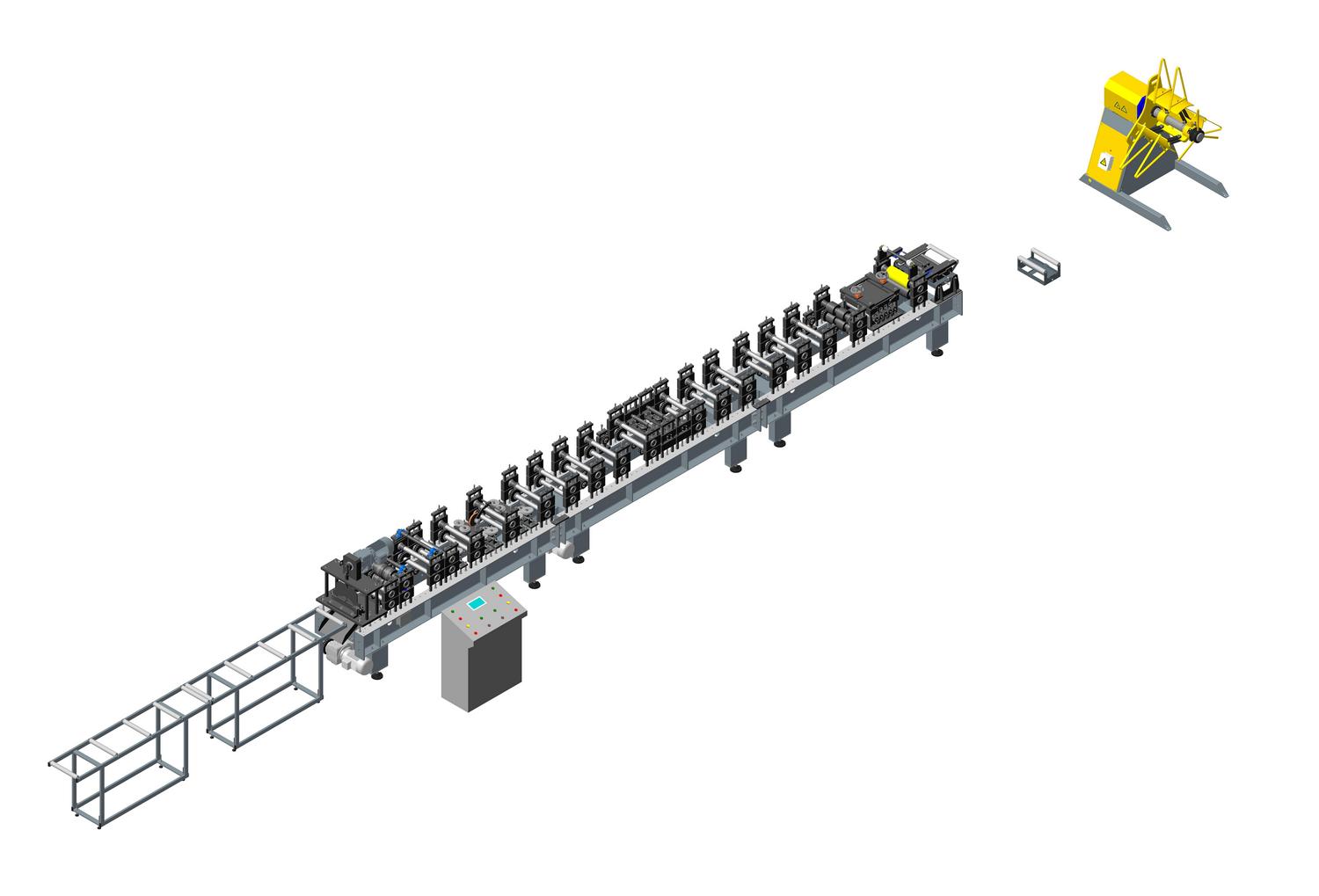

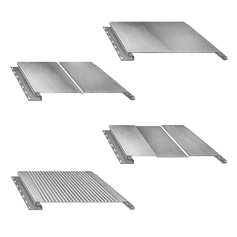

Equipment

Decoiler

1 pc.

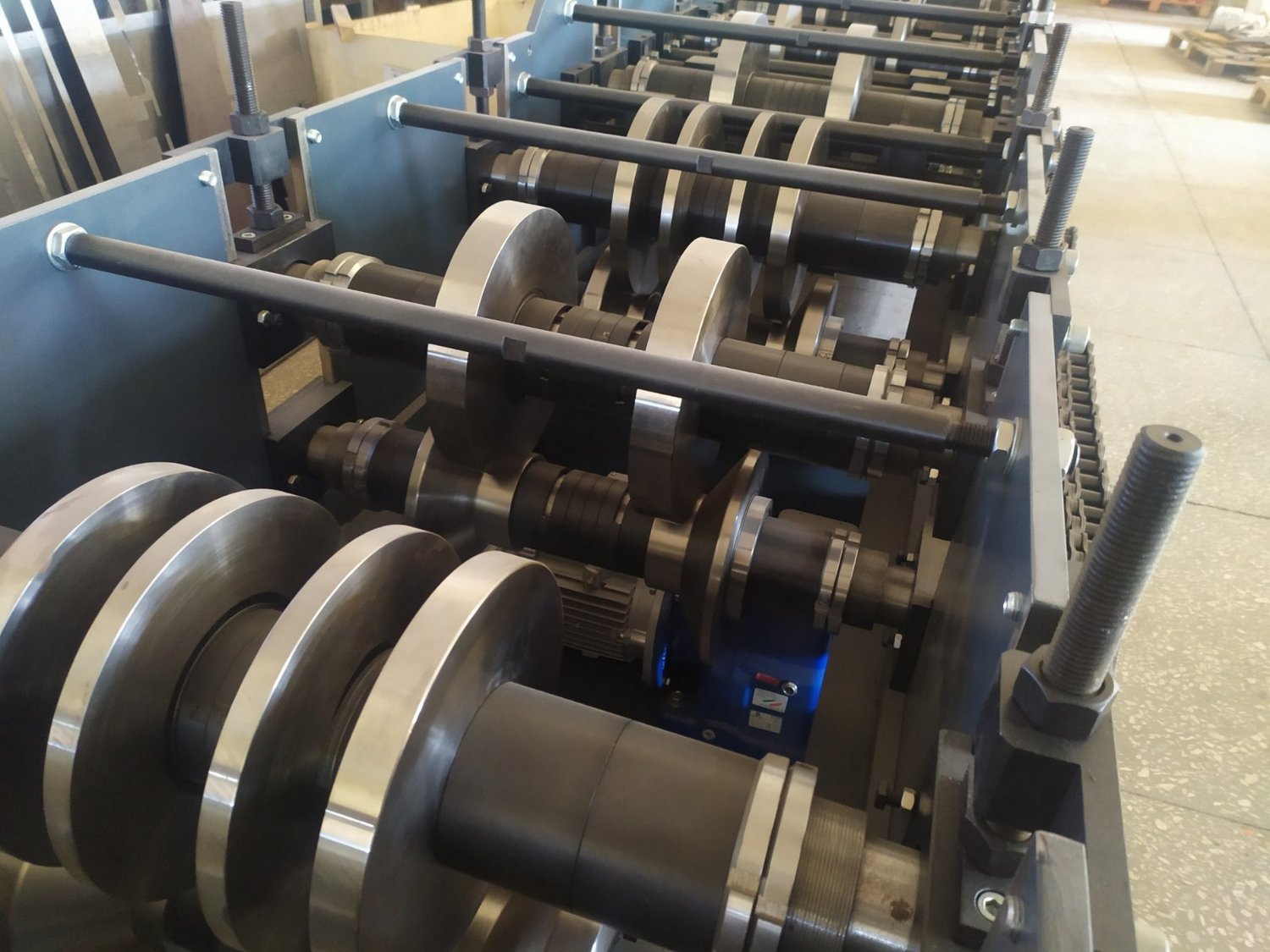

Roll forming mill

1 pc.

Cutting device

1 pc.

Receiving table-roller conveyor

2 pcs.

Control cabinet

1 pc.

Options

- Fences, sensors, cameras in critical areas, monitors;

- Tracking module (Work, maintenance, simple, remote access, statistics. Tracking the work of the line by management.);

- Logistics and packaging.

Description of the line

The production of lines for the rolling of linear panels is one of the activities of Meer group sro.

Linear panels are made of rolled sheet steel or aluminum with a protective and decorative coating of various colors. The thickness of rolled metal for the manufacture of linear panels ranges from 0.45 mm to 1.0 mm. Initially, rolled metal is cut into strips of the required width on machine tools, and then profiled.

Specifications

Processed material

Thin-sheet galvanized steel, rolled thin-sheet with a protective and decorative paint coating (steel grade DC01, DC04, application: cold rolling)

Thickness of the processed material

0,45-1,0 mm

Workpiece width

According to drawings

Profiling speed

25 run. m./min

Accuracy of cutting

± 5 mm

Type of roll forming mill

rack

Work mode

Semi-automatic

The maximum length of the profile accepted by the receiving table

4000 mm.

Control cabinet

Provides automatic operation of the line after filling the material into the roll forming machine, equipped with a frequency converter

Operation staff

2 persons