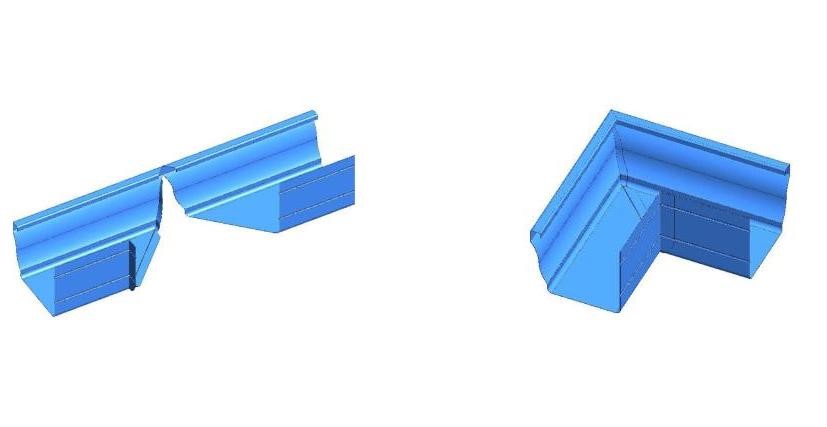

Rectangular gutter systems

Solutions inspired by your ideas and our experience

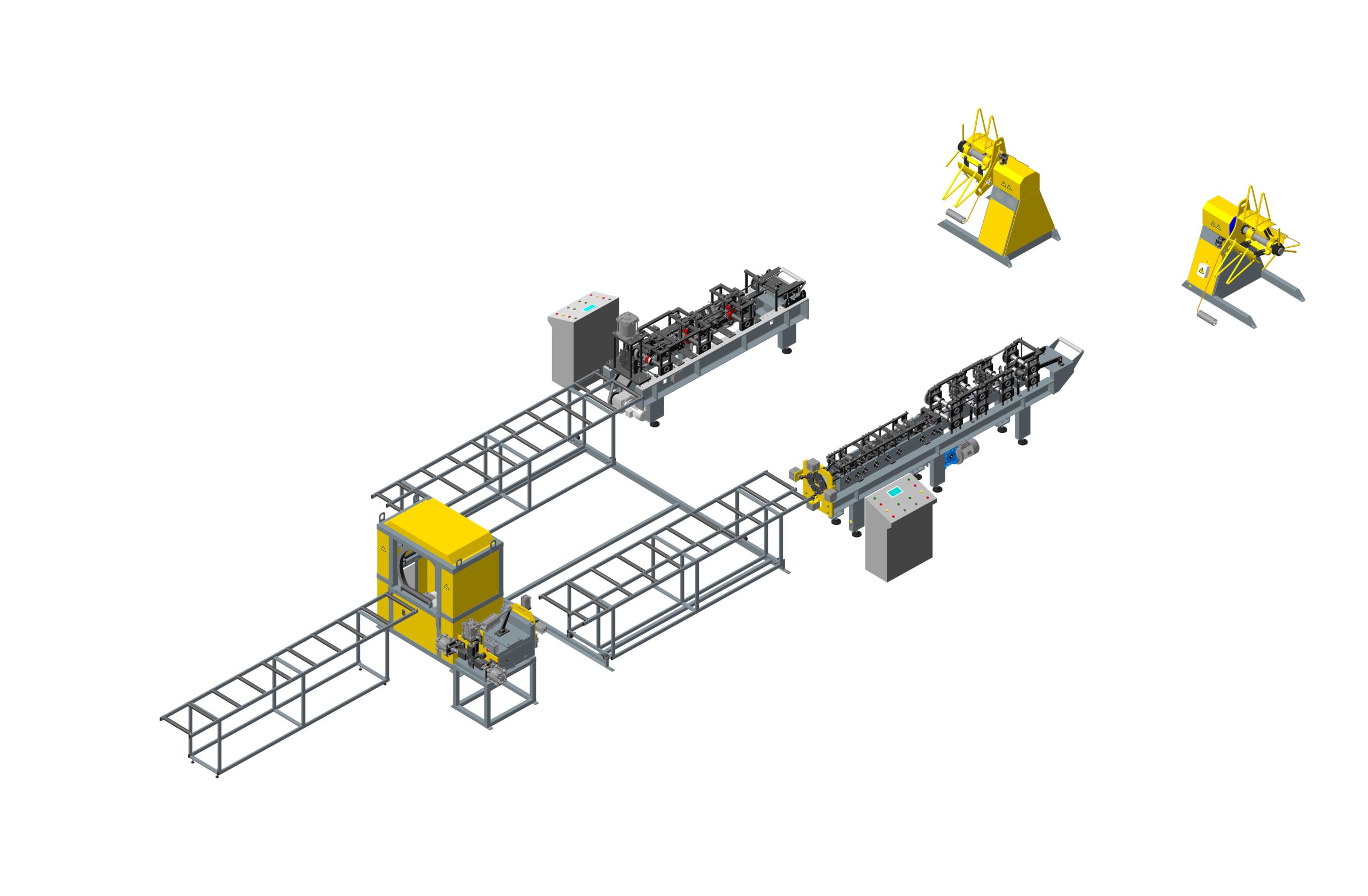

Equipment

Decoiler

1 set;

Roll forming mill

1 set;

Cutting device

1 set;

Receiving table

1 set;

Control cabinet

1 set;

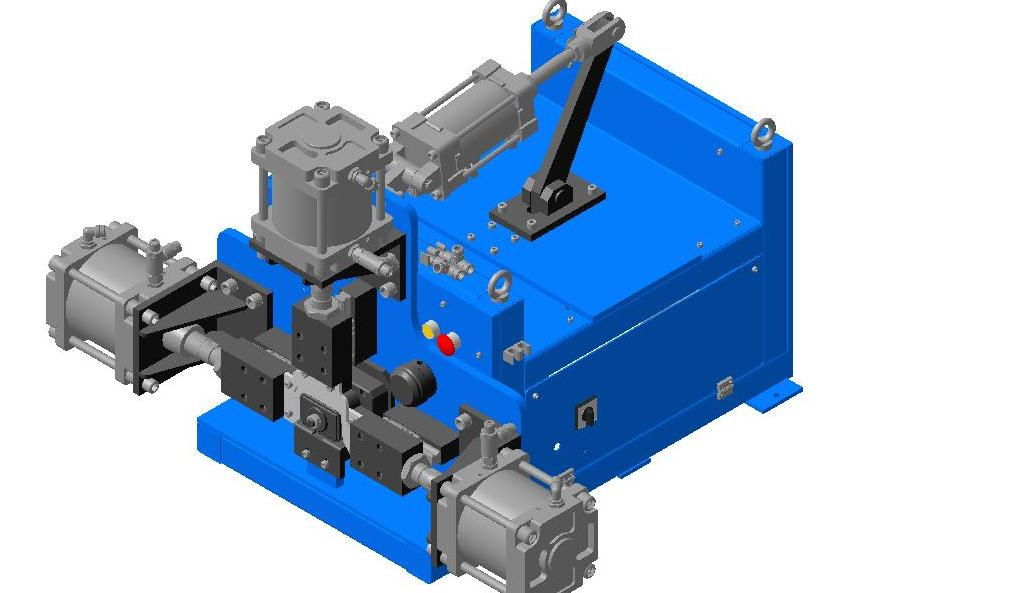

Press-stamp

1 set;

Stamping equipment

Options

- Double stamps;

- Additional press stamps;

- Robots;

- Fences, sensors, cameras of critical areas, monitors;

- Tracking module (Operation, maintenance, simple, remote access, statistics. Tracking of the work by the management).

- Logistics and packaging.

Description of the line

The lines are designed for the production of a rectangular downpipe, a figured gutter, as well as the entire list of die equipment for the manufacture of additional elements (pipe funnel, pipe and gutter holders, plugs, gutter elbows, gutter connectors, pipe elbows, etc.) profiles from thin sheet steel thickness from 0.4 to 0.6 mm.

Specifications

Processed material

Thin sheet galvanized steel, with plastisol or pural coating. Sheet steel class: DX52D+Z (EN 10142:2000)

Thickness of the processed material

0,4-0,6 mm

Workpiece width

According to drawings

Profiling speed

15 run.n./min.

Cut-off accuracy

± 2mm.

Type of roll forming mill

Rack

The control cabinet ensures automatic operation of the line after filling the material into the roll forming machine

Equipped with frequency converter and CNC

Operation staff

1-5 persons

Type of press for the production of additional elements

Negotiated separately for each profile

Stamping equipment

It is developed separately for each project. Different profiles require a separate die set.